You may be wondering why the hardener is such an essential component in liquid glass epoxy. Well, let’s clear that up for you.

The hardener plays a crucial role in initiating the curing process, ensuring that the epoxy resin transforms into a strong and durable material. But that’s not all – the type of hardener used can also impact the transparency and refractive index of the cured epoxy finish.

So, if you’re curious to know more about how the hardener achieves these effects and what factors to consider when choosing the right hardener, keep reading.

Key Takeaways

- The choice of hardener in liquid glass epoxy is crucial for achieving the desired transparency, durability, and performance of the cured finish.

- Different types of hardeners offer specific properties and impacts on the curing process, such as the glass transition temperature, curing speed, and mechanical properties.

- The temperature and humidity during the curing process can significantly affect the reaction rate and final properties of the cured epoxy.

- The correct mixing ratio of epoxy resin and hardener is essential for optimal curing results, as a higher or lower mixing ratio can lead to inadequate curing or poor mechanical properties.

Importance of Hardener in Liquid Glass Epoxy

The choice of hardener in liquid glass epoxy plays a crucial role in determining the transparency and performance of the cured finish. When it comes to epoxy resin systems, amine curing agents are commonly used as hardeners. These amine-curing agents are known for their ability to provide a high glass transition temperature, which enhances the mechanical properties of the epoxy. This is important because a high glass transition temperature ensures that the epoxy remains stable and durable even under high temperatures.

In addition to enhancing the mechanical properties, the choice of hardener also affects the chemical resistance of the cured epoxy finish. Different hardeners have different chemical resistance properties, which can be crucial in certain applications. For example, if the epoxy is going to be exposed to harsh chemicals or solvents, it’s important to choose a hardener that provides excellent chemical resistance.

Furthermore, the choice of hardener can also impact the water-uptake kinetics and degradation behavior of the cured epoxy finish, especially in warm and humid conditions. It’s important to select a hardener that can withstand these conditions and maintain the performance of the epoxy over time.

Curing Process of Liquid Glass Epoxy

When it comes to the curing process of liquid glass epoxy, there are several factors to consider.

First, the curing time is influenced by factors such as the type and amount of hardener used, as well as the ambient temperature and humidity.

Second, the proper mixing ratio of the epoxy resin and hardener is crucial for achieving optimal curing results.

Lastly, it’s important to note that the curing process can be affected by the presence of additives or fillers, which may require adjustments to the curing time.

Curing Time Factors

To understand the factors influencing the curing time of liquid glass epoxy, one must consider the type and amount of hardener used in the epoxy resin. The curing period of liquid glass epoxy is affected by various factors such as the initial urea added, urea added after post-refluxing, and sorbitol. These factors can influence the duration of the curing process when hardeners are present.

The choice of hardener also plays a significant role in determining the water-uptake kinetics and degradation behavior of glass fibers embedded in the epoxy matrix, particularly in warm, humid conditions. Different types of hardeners, including aromatic diamino compounds, catalysts, and polymeric additives, offer specific properties and impacts on the curing process.

Characterizing and analyzing the curing period of liquid glass epoxy can be achieved through techniques like Transmission Electron Microscopy (TEM). This allows for a better understanding of the interaction between the resin and the hardener, ultimately influencing the overall curing time.

Temperature and Humidity

Considering the impact of temperature and humidity on the curing process of liquid glass epoxy, it’s crucial to examine the interplay between these environmental factors and the choice of hardener in order to achieve optimal curing results.

Temperature plays a significant role in epoxy curing, as it affects the reaction rate and the time required for the epoxy to cure. Higher temperatures generally accelerate the curing process, while lower temperatures slow it down. However, it’s important to note that extreme temperatures can negatively impact the final properties of the cured epoxy.

Humidity, on the other hand, affects the moisture content of the epoxy system. High humidity can introduce moisture into the mixture, leading to inadequate curing and reduced mechanical properties.

Therefore, controlling temperature and humidity during the curing process is essential for achieving the desired performance of liquid glass epoxy.

Mixing Ratio Importance

The mixing ratio is a critical factor in the curing process of liquid glass epoxy, as it directly impacts the final properties and performance of the cured epoxy. The ratio refers to the proportion of resin to hardener used in the mixture. Achieving the correct mixing ratio is essential for obtaining optimal curing results.

To illustrate the importance of the mixing ratio, let’s consider the following table:

| Mixing Ratio | Resin (ml) | Hardener (ml) |

|---|---|---|

| 2:1 | 100 | 50 |

| 3:1 | 100 | 33.3 |

| 4:1 | 100 | 25 |

As seen in the table, the amount of hardener decreases as the mixing ratio increases. This means that a higher mixing ratio will result in a slower curing process. On the other hand, a lower mixing ratio may lead to insufficient curing or poor mechanical properties.

It is crucial to follow the recommended mixing ratio provided by the manufacturer to ensure proper curing and achieve the desired performance of the cured epoxy.

Chemical Reaction Initiated by Hardener

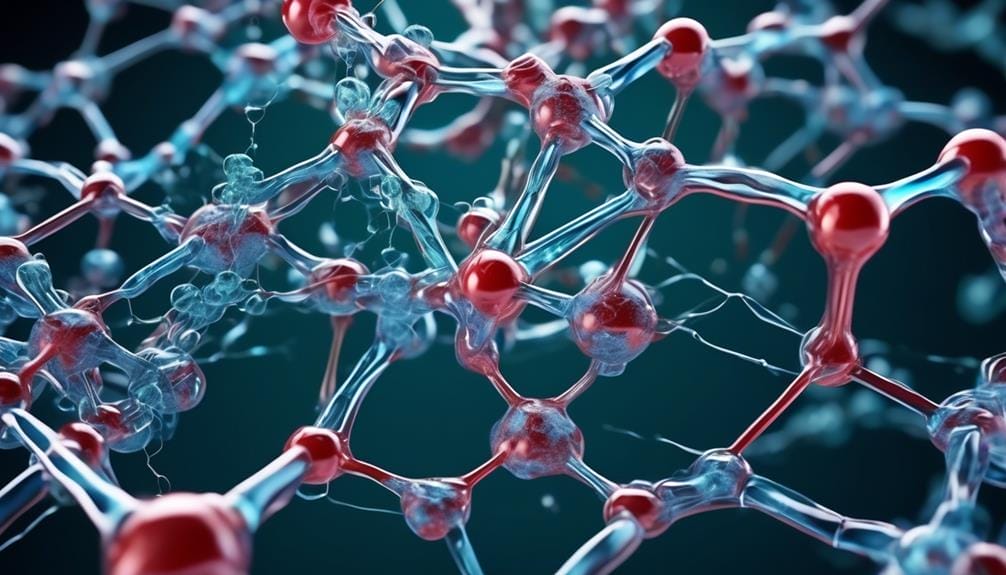

The hardener in liquid glass epoxy initiates a chemical reaction that’s crucial in determining the transparency and refractive index of the cured finish. When the hardener is mixed with the liquid glass epoxy, a crosslinking process begins. This chemical reaction involves the hardener molecules reacting with the epoxy molecules to form a three-dimensional network of interconnected chains. This network is responsible for the cured finish’s unique properties.

During the chemical reaction, the hardener molecules act as a catalyst, accelerating the curing process. They provide the necessary energy for the epoxy molecules to react and form strong bonds. The speed of the reaction depends on the type and amount of hardener used, as well as the environmental conditions such as temperature and humidity.

The chemical reaction initiated by the hardener also affects the transparency of the cured finish. The crosslinking of the epoxy molecules forms a dense and uniform structure, which contributes to the high transparency of liquid glass epoxy. Additionally, the refractive index of the cured finish is influenced by the arrangement of the molecules during the chemical reaction. This, in turn, affects the way light is transmitted and reflected, giving the cured finish its glass-like appearance.

Crosslinking of Epoxy Molecules

As the hardener in liquid glass epoxy initiates the desired chemical reaction, the epoxy molecules undergo crosslinking, leading to the formation of strong covalent bonds and the creation of a robust three-dimensional network. Crosslinking is a crucial step in the curing process of epoxy resin, as it imparts exceptional strength, durability, and chemical resistance to the final product.

During cross-linking, the hardener molecules react with the epoxy resin molecules, causing them to join together and form a three-dimensional network. This network is composed of interconnected chains of epoxy molecules held together by covalent bonds. The presence of these bonds enhances the mechanical properties of the cured epoxy, making it highly resistant to deformation and fracture. Additionally, the crosslinked epoxy exhibits improved resistance to chemical corrosion, heat, and impact.

The degree of crosslinking can be controlled by adjusting the ratio of epoxy resin to hardener—a higher concentration of hardener results in a greater number of crosslinks and a more rigid cured epoxy. Conversely, a lower concentration of hardener produces a more flexible epoxy with fewer crosslinks. Therefore, achieving the desired performance characteristics of the cured epoxy relies on proper crosslinking of the epoxy molecules.

Creating a Strong Bond With Hardener

To create a strong bond with the hardener in liquid glass epoxy, specific types of hardeners are used for their unique purposes. Different types of hardeners are selected based on their compatibility with epoxy resins and the desired cure time. The hardener plays a crucial role in the curing process, as it reacts with the epoxy resin to initiate crosslinking and create a strong and durable bond.

When selecting a hardener for creating a strong bond, it’s important to consider factors such as the type of material being bonded and the intended application. For example, suppose you’re working on a project that requires a clear finish. In that case, it’s recommended to use a clear epoxy resin along with a compatible hardener to ensure transparency and maintain the desired aesthetic.

Additionally, the cure time of the epoxy resin is influenced by the hardener used. Some hardeners are designed to accelerate the curing process, allowing for faster project completion. On the other hand, other hardeners may be used to extend the cure time, providing more flexibility and allowing for better workability.

Functions of Hardener in Liquid Glass Epoxy

The hardener in liquid glass epoxy plays two crucial functions: the curing process and the chemical reaction.

The hardener initiates the curing process by triggering the crosslinking of the epoxy molecules, leading to the hardening of the resin.

Additionally, the hardener chemically reacts with the epoxy, resulting in a strong and durable bond.

Understanding these functions is essential for achieving the desired properties and performance of liquid glass epoxy.

Hardener’s Curing Process

How does the hardener in liquid glass epoxy contribute to the curing process and determine the final properties and functionality of the epoxy finish? The hardener in liquid glass epoxy plays a vital role in the curing process, which ultimately determines the final properties and functionality of the epoxy finish. The type of hardener used affects the rate of reaction and the cure temperature required for the epoxy to harden. Amine hardeners are commonly used in liquid glass epoxy systems due to their high-temperature resistance and fast curing capabilities. The hardener influences various properties of the cured epoxy, such as transparency, durability, and refractive index. By choosing the appropriate hardener, specific performance characteristics can be achieved. The following table summarizes the key aspects of the hardener’s role in the curing process and its impact on the final properties of liquid glass epoxy.

| Aspect | Hardener’s Role |

|---|---|

| Rate of Reaction | Determines the speed at which the epoxy cures, affecting the time required for the hardening process. |

| Cure Temperature | It influences the temperature at which the epoxy needs to be cured, affecting the energy requirements. |

| Final Properties | Impacts properties such as transparency, durability, and refractive index of the cured epoxy. |

Hardener’s Chemical Reaction

As the hardener in liquid glass epoxy initiates a chemical reaction with the resin, it facilitates the crucial process of curing or hardening the epoxy. This chemical reaction occurs between the epoxy groups in the resin and the hardener, resulting in the formation of a strong and durable bond.

The hardener’s role in this reaction is to act as a catalyst, promoting the crosslinking of the epoxy molecules. Different types of hardeners, such as aliphatic amines or aromatic amines, can be used depending on the desired properties of the cured epoxy.

The choice of hardener also affects the working time of the epoxy, determining the time available for application and manipulation before it starts to harden. Additionally, the hardener plays a crucial role in controlling the curing period, affecting the speed and duration of the curing process.

Characteristics of Hardener in Epoxy Resins

Utilizing various types of hardeners in liquid glass epoxy resins plays a crucial role in determining the transparency of the resulting cured finish. The characteristics of the hardener have a significant impact on the epoxy curing process and the mechanical properties of the final product.

One important characteristic to consider is the glass transition temperature (Tg) of the hardener. Tg refers to the temperature at which the hardener transitions from a rigid, glassy state to a more flexible, rubbery state. The Tg of the hardener should be compatible with the desired application temperature range of the epoxy resin. If the Tg of the hardener is too low, the cured epoxy may become soft and lose its mechanical strength at elevated temperatures.

Another characteristic to consider is the curing speed of the hardener. Different types of hardeners have different reactivity rates, which can affect the curing time of the epoxy resin. In industries where quick curing is desired, such as in manufacturing processes, a fast-reacting hardener would be preferred.

Furthermore, the mechanical properties of the cured epoxy resin can also be influenced by the type of hardener used. Some hardeners may enhance the strength and toughness of the epoxy, while others may improve its resistance to chemical or environmental factors.

Role of Hardener in Epoxy Curing

The role of the hardener in epoxy curing is crucial in determining the transparency and mechanical properties of the cured finish. The hardener interacts with the epoxy resin during the curing process, resulting in a strong and durable material.

Here are some key points about the role of the hardener in epoxy curing:

- Transparency: The type of hardener used plays a significant role in determining the transparency of the cured epoxy finish. Different hardeners can result in varying levels of transparency, allowing for customization based on the desired aesthetic outcome.

- Mechanical properties: The hardener influences the mechanical properties of the cured epoxy. By selecting the appropriate hardener, the epoxy can be tailored to have specific characteristics such as flexibility, hardness, or impact resistance.

- Refractive index: The role of the hardener in epoxy curing also affects the refractive index of the material. The refractive index measures how light moves through the epoxy compared to a vacuum. By adjusting the hardener, the refractive index can be optimized to achieve the desired level of transparency.

- Appearance: Epoxy is known for its high transparency, giving it the appearance of liquid glass. The combination of a low refractive index and high transparency makes epoxy suitable for various applications, including coatings, laminates, and decorative items.

- Cure time: Different hardeners have varying cure times, affecting the overall curing process of the epoxy. The choice of hardener should be made based on the desired curing time and the application requirements.

Hardener’s Impact on Durability and Strength

The choice of hardener in liquid glass epoxy has a significant impact on both the durability and strength of the cured finish.

The chemical reaction between the hardener and epoxy enhances its ability to withstand wear and tear over time, making it more durable.

Additionally, the type of hardener used can influence the structural strength of the epoxy, making it crucial to select the appropriate hardener for specific applications.

Hardener’s Chemical Reaction

To optimize the durability and strength of epoxy, it’s essential to understand the chemical reaction between the hardener and the resin. The hardener’s chemical reaction significantly impacts the properties and performance of the cured epoxy finish. Here are some key points to consider:

- The type of hardener used determines the level of resistance that the cured epoxy will have against various factors such as chemicals, heat, and physical stress.

- The chemical reaction between the hardener and the resin is what initiates the curing process of the epoxy.

- This chemical reaction results in the formation of crosslinks, which are responsible for the epoxy’s high strength and durability.

- Different hardeners have different cure times, allowing for adjustments to be made based on specific application requirements.

- Understanding the chemical reaction between the hardener and the epoxy resin is crucial for selecting the right combination to achieve the desired durability and strength for different applications.

Enhancing Epoxy’s Durability

Understanding the impact of the hardener on durability and strength is crucial in maximizing the performance of epoxy finishes.

The type of hardener used plays a significant role in enhancing the durability of the epoxy. For instance, amber-hued hardeners are often chosen to increase the strength and resilience of the epoxy finish. This is particularly important in projects where durability is prioritized, such as boat construction.

Using the right hardener ensures that the epoxy finish can withstand harsh conditions and maintain its integrity over time. Moreover, the choice of hardener can also influence the water resistance of the epoxy, further enhancing its durability.

Therefore, selecting the appropriate hardener is essential for achieving long-lasting and durable epoxy finishes.

Impact on Structural Strength

Enhancing the durability and strength of liquid glass epoxy relies heavily on the choice of hardener and its impact on structural integrity. The hardener’s influence on the epoxy’s cure rates, low viscosity, and overall structural integrity is crucial in achieving the desired strength.

Here are some key points to consider:

- Different hardeners serve specific purposes, altering the durability and strength of the epoxy finish.

- Amber-hued hardeners, despite slightly tinting the finish, are commonly used in non-aesthetic projects like boat construction for enhanced structural integrity.

- The curing period of the resin is affected by the hardener, with shorter curing periods preferred in industries such as coating, plywood, fiberboard, paper, and plastic for improved structural strength.

- The type of hardener used in composite materials significantly affects water-uptake kinetics, degradation behavior, and overall durability in warm, humid conditions.

The choice of hardener plays a crucial role in determining the structural strength and durability of liquid glass epoxy. Careful consideration and selection are necessary to achieve the desired results.

Choosing the Right Hardener for Liquid Glass Epoxy

Choosing the right hardener for your liquid glass epoxy is a critical decision that directly impacts the transparency and curing period of the finished product. When selecting a hardener, it’s important to consider the specific requirements of your project.

If you’re looking for a low cure temperature, there are hardeners available that can cure at room temperature, allowing for a more convenient and efficient curing process.

If you’re working with a Deep Pour application, where the epoxy is poured at a thickness greater than 1 inch, it’s essential to choose a hardener that’s specifically designed for this purpose. Deep-pour hardeners have a slower curing time, allowing the epoxy to cure properly without excessive heat generation or cracking.

For Table Top Epoxy applications, where a crystal clear, glossy finish is desired, it’s crucial to select a hardener that provides excellent clarity and minimal color tinting. Some hardeners may have an amber hue, which can slightly tint the finish and affect the overall aesthetic appeal of the cured epoxy.

Additionally, it’s important to consider the environmental effects of the hardener. Some hardeners may have water-uptake kinetics or degradation behavior that can impact the long-term durability of the epoxy resin.

Understanding the different types and properties of hardeners, including aromatic diamino compounds, catalysts, and latent hardeners, is essential for selecting the most suitable hardener for your liquid glass epoxy application. By carefully considering these factors, you can ensure that you choose the right hardener to achieve the desired transparency and curing period for your finished product.

Tips for Using Hardener in Liquid Glass Epoxy

To ensure optimal results when using hardener in liquid glass epoxy, follow these tips for a successful application:

- Choose the right hardener: Select a hardener that’s compatible with your liquid glass epoxy and suits the desired finish. Different hardeners can affect the transparency and tint of the cured epoxy.

- Proper mixing ratio: Accurately measure and mix the hardener and epoxy resin in the recommended ratio. Deviating from the specified proportions can lead to incomplete curing or compromised strength.

- Thorough mixing: Mix the hardener and epoxy resin thoroughly, ensuring a homogeneous blend. Incomplete mixing can result in uneven curing, weak spots, and reduced clarity.

- Appropriate application temperature: Follow the manufacturer’s guidelines regarding the optimal temperature for applying the epoxy. Extreme temperatures can affect the curing process and the final appearance of the epoxy finish.

- Allow sufficient curing time: Patience is key when working with liquid glass epoxy. Allow the epoxy to cure fully according to the manufacturer’s instructions. Rushing the curing process can result in a subpar finish.

Frequently Asked Questions

What Is the Role of Hardener?

The importance of hardener in epoxy is significant. It determines transparency and affects the refractive index, ensuring objects are coated without distortion. Choosing the right hardener is crucial for durability, but using too much or temperature variations can impact the hardening process.

What Does Hardener Do to Resin?

The hardener strengthens the resin by initiating a chemical reaction that crosslinks the molecules. The correct hardener-to-resin ratio is crucial for optimal curing and maximum strength. Factors to consider when selecting a hardener include curing time, temperature, and desired finish.

What Happens if You Use Too Little Hardener in Epoxy?

If you use too little hardener in epoxy, disaster strikes! Your finish remains sticky, prone to damage, and lacks chemical resistance. Indentations, marks, and a hazy appearance haunt your epoxy. Accurate hardener measurements are crucial!

How Long Does Liquid Glass Epoxy Take to Harden?

Liquid glass epoxy typically takes 24-72 hours to harden fully. The curing process is triggered by adding a hardener. Factors like temperature, humidity, and ventilation can affect hardening time. Techniques to speed up curing include using a higher ratio of hardener to epoxy. Common mistakes include using too little hardener.

Conclusion

In conclusion, the role of the hardener in liquid glass epoxy can’t be overstated. It initiates the curing process, creating a solid and durable material. The chemical reaction between the hardener and epoxy resin forms a strong bond, ensuring the longevity and strength of the finished product.

Choosing the right hardener is crucial, as it can impact the transparency and refractive index of the cured epoxy. So, remember to select your hardener wisely to achieve the desired properties and application for your liquid glass epoxy.