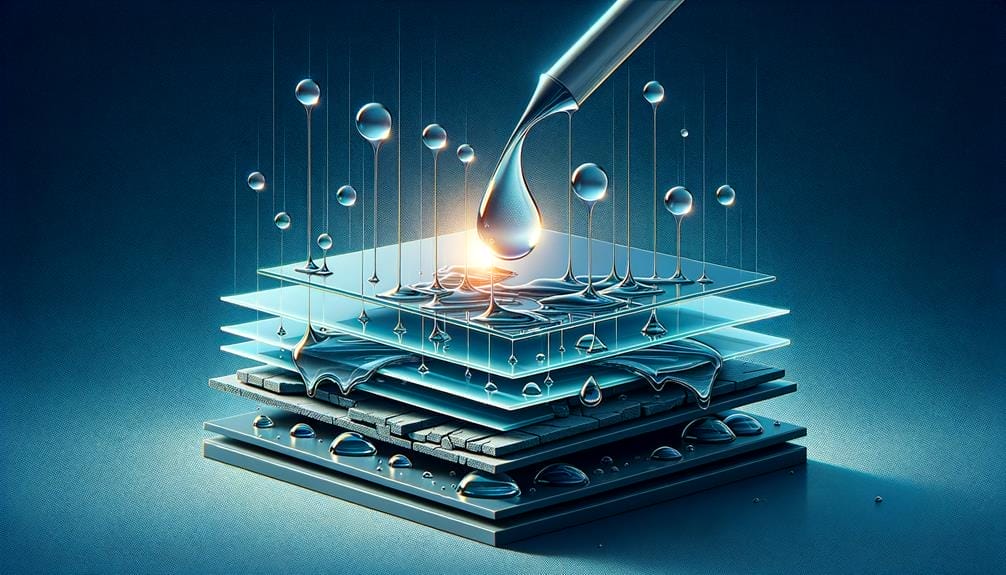

They say that when it rains, it pours. But what if you could protect your surfaces from the relentless downpour, ensuring they remain pristine and water-resistant? That’s where liquid glass epoxy comes in.

With its seamless application and unmatched durability, this innovative solution offers a reliable way to waterproof a variety of surfaces. But how does it work? And why should you consider using it?

In this discussion, we will explore the benefits of liquid glass epoxy, surface preparation techniques, application methods, and its effectiveness in waterproofing different materials.

So, if you’re looking for a solution to keep water at bay, keep reading to discover the wonders of liquid glass epoxy.

Key Takeaways

- Waterproofing with liquid glass epoxy provides numerous benefits, including preventing water damage, extending material lifespan, reducing mold and mildew growth, and protecting against corrosion and rust.

- Proper surface preparation is crucial for effective waterproofing, including thorough cleaning, repairing any cracks or damaged areas, and using isopropyl alcohol for adhesion.

- Removing old sealant is important to ensure a smooth and even base for the new waterproofing application, and it can be done through scraping, sanding, and using solvent or adhesive remover.

- Ensuring a smooth application involves cleaning the surface with isopropyl alcohol, using plastic sheeting for a dust-free environment, removing air bubbles with a heat gun, and allowing for proper curing for up to 72 hours.

Benefits of Liquid Glass Epoxy

Liquid Glass Epoxy offers a multitude of benefits that make it the ideal choice for waterproofing projects. One of the standout advantages of this epoxy resin is its deep pour capability. With the ability to pour 2-4 inches, it saves you time and effort by reducing the number of layers required to achieve the desired thickness. This means faster completion times and less hassle during the application process.

Not only does Liquid Glass Epoxy offer deep pour capability, but it also provides a crystal clear finish that’s unmatched in the industry. The glossy outcome adds a touch of elegance to any surface it’s applied to, making it a popular choice for both residential and commercial projects.

In addition to its visual appeal, liquid glass epoxy is known for its durability. It offers exceptional strength and structural integrity, making it suitable for high-traffic areas that require a robust waterproofing solution.

Another benefit of Liquid Glass Epoxy is its bubble-less technology. When mixing the epoxy, bubbles naturally form. However, this epoxy resin effortlessly allows bubbles to rise to the surface, ensuring a smooth and flawless finish. To further eliminate any remaining bubbles, lightly torching the surface or using isopropyl alcohol can be used.

Surface Preparation for Waterproofing

Before applying the liquid glass epoxy for waterproofing, it’s crucial to prepare the surface properly.

Start by cleaning the surface thoroughly and removing any debris or previous coatings.

Make sure to repair any cracks or damaged areas to ensure a complete waterproofing barrier.

Cleaning the Surface

To ensure a strong and resilient waterproofing finish, it’s crucial to properly clean and prepare the surface by removing any dirt, debris, or previous coatings.

Before applying the seal coat of Liquid Glass Epoxy Resin, the surface must be clean, dry, and at least 70 degrees Fahrenheit.

Start by cleaning the surface with Isopropyl Alcohol 90%+ to ensure proper adhesion of the waterproofing product.

Lay down plastic sheeting for easy cleanup during the surface preparation process.

Use sandpaper to remove any rough patches or imperfections on the surface.

Thoroughly clean the surface, making sure to remove all dust and residue.

The surface must be smooth and free from any contaminants before applying the Deep Pour layer of Liquid Glass Epoxy Resin for optimal waterproofing performance.

Removing Old Sealant

Start by thoroughly removing any old sealant from the surface to ensure a smooth and even base for the new waterproofing application. This step is crucial in preparing the surface for the application of Deep Pour Epoxy or Liquid Glass.

To remove the old sealant, use a scraper or sandpaper to scrape and sand the surface, eliminating any remaining sealant or residue. This process promotes better adhesion for the new waterproofing material.

If stubborn remnants of old sealant persist, a solvent or adhesive remover can be used to dissolve and eliminate them.

Once the old sealant has been removed, it’s essential to clean the surface thoroughly with a suitable cleaner. This ensures that the new sealant bonds effectively and performs optimally, providing long-lasting waterproofing protection.

Ensuring Smooth Application

For a smooth and flawless application of Liquid Glass Epoxy, ensure that the surface is clean, dry, and at least 70 degrees Fahrenheit. Here are four key steps to follow for surface preparation to achieve a professional waterproofing finish:

- Clean the surface: Prior to applying the seal coat, use Isopropyl Alcohol 90%+ to clean the surface thoroughly. This will ensure strong adhesion and a resilient waterproofing surface.

- Lay down plastic sheeting: To maintain a dust-free environment and facilitate easy cleanup, lay down plastic sheeting before starting the application process. This will help prevent dust particles from compromising the smoothness of the finish.

- Remove air bubbles: After pouring the Liquid Glass Epoxy mixture into the mold at the desired depth, use a heat gun to remove any trapped air bubbles gently. This step is crucial to achieve a bubble-free and crystal-clear waterproofing application.

- Allow for proper curing: To ensure a strong and long-lasting finish, allow the surface to cure for up to 72 hours in a dust-free environment. This will optimize the curing process and result in a smooth, waterproof surface.

Application Techniques for Liquid Glass Epoxy

When applying Liquid Glass Epoxy, ensure a smooth and precise application to achieve a flawless and durable finish. To help you achieve the best results, here are some application techniques for using Liquid Glass Epoxy:

- Prepare the surface: Before applying the epoxy, make sure the surface is clean, dry, and free of any dust or debris. Sanding the surface can help create a better bond.

- Mix the epoxy: Follow the manufacturer’s instructions for mixing the Liquid Glass Epoxy. It’s important to mix it thoroughly to ensure proper curing and adhesion.

- Apply a seal coat: Start by applying a thin seal coat of epoxy to the surface. This helps to seal any pores and prevents air bubbles from forming during the deep pour.

- Pour the epoxy: Slowly pour the Liquid Glass Epoxy onto the surface, ensuring an even distribution. For deep pour applications, it’s recommended to pour in layers, allowing each layer to partially cure before pouring the next.

- Remove air bubbles: To remove any air bubbles that may have formed, use a heat gun on low settings. Move the heat gun in a sweeping motion over the surface, being careful not to overheat the epoxy.

Waterproofing Concrete With Liquid Glass Epoxy

When it comes to waterproofing concrete, utilizing Liquid Glass Epoxy offers a range of benefits.

This innovative epoxy solution provides a durable and long-lasting waterproof barrier, protecting the concrete from water damage and moisture infiltration.

Concrete Waterproofing Benefits

To achieve superior waterproofing for your concrete surfaces, consider using Liquid Glass Epoxy, a high-quality and durable solution that provides a clear and glass-like finish. Here are four benefits of using Liquid Glass Epoxy for concrete waterproofing:

- Deep Pour Capability: Liquid Glass® Deep Pour Epoxy offers a deep pour capability of 2-4 inches, allowing for a single pour application. This eliminates the need for multiple pours and ensures a seamless and uniform surface.

- Excellent Waterproofing: Liquid Glass Epoxy forms a strong and impenetrable barrier on the concrete surface, preventing water penetration and potential damage caused by moisture.

- Enhanced Durability: As a two-part epoxy casting resin, Liquid Glass Epoxy provides a tough and long-lasting surface that can withstand heavy foot traffic, chemicals, UV rays, and other environmental factors.

- Easy Application: Liquid Glass Epoxy has a low-viscosity formulation, making it easy to apply and allowing for effortless bubble removal during the curing process. It can be used as a seal coat or as a top coat for added protection.

With Liquid Glass Epoxy, you can ensure effective waterproofing for your concrete surfaces while enjoying the benefits of a clear and durable finish.

Applying Liquid Glass Epoxy

For optimal waterproofing of your concrete surfaces, the application of Liquid Glass Epoxy is a reliable and high-performing solution that guarantees a clear and durable finish.

When applying Liquid Glass Epoxy, it’s important to ensure a clean and smooth surface. Begin by cleaning the concrete thoroughly, removing any dirt, dust, or debris. If needed, use sandpaper to smoothen any rough areas.

Once the surface is clean and smooth, mix the epoxy according to the manufacturer’s instructions. Pour the epoxy onto the concrete, making sure to distribute it evenly. Liquid Glass Epoxy offers deep pour capabilities, allowing you to pour anywhere between 2 to 4 inches thick.

After pouring, use a seal coat to enhance the waterproofing properties of the epoxy further. Allow the epoxy to cure according to the recommended timeframe before subjecting it to heavy use.

With Liquid Glass Epoxy, you can achieve a glass-like finish that not only waterproofs your concrete surface but also provides unmatched durability and longevity.

Waterproofing Wood Surfaces With Liquid Glass Epoxy

To waterproof wood surfaces, the first step is to prepare the area by ensuring it’s clean and free of any dirt or debris. Once the surface is clean, you can proceed with the application of Liquid Glass® Deep Pour Epoxy.

Here are the steps to successfully waterproof wood surfaces using this epoxy:

- Deep Pour: Liquid Glass® Deep Pour Epoxy is designed for applications where a thick coat is required. It can be poured 2-4 inches thick, providing excellent coverage and waterproofing capabilities for wood surfaces.

- Seal Coat: Before applying the deep pour epoxy, it’s recommended to apply a seal coat. This will help to seal the wood and prevent any moisture from seeping into the surface, ensuring a more effective waterproofing solution.

- Tacky to Touch: Once the seal coat has been applied, allow it to become tacky to the touch. This will ensure proper adhesion between the seal coat and the deep-pour epoxy, creating a more durable and long-lasting waterproof barrier.

- Cure Time: After applying the deep pour epoxy, allow sufficient time for it to cure. Follow the manufacturer’s instructions for the recommended curing time. This will ensure that the epoxy fully hardens and provides the maximum waterproofing protection for your wood surface.

Liquid Glass Epoxy for Waterproofing Countertops

When waterproofing countertops, Liquid Glass Epoxy offers a reliable and high-performance solution. With its deep pour capability of 2-4 inches, it’s specifically designed to provide a crystal-clear finish on surfaces such as countertops. The low-viscosity formulation of Liquid Glass Epoxy ensures that bubbles rise to the surface during the curing process, resulting in a flawless and bubble-free finish without the need for additional steps.

This epoxy is proudly made in the USA by Fiberglass Coatings, Inc., adhering to high-quality manufacturing standards and supporting the local economy.

Liquid Glass Epoxy’s deep pour capability saves time and eliminates the need for multiple pours, making it an ideal choice for waterproofing countertops. It creates a clear and glass-like finish, giving your countertop a professional and polished appearance. The easy mixing process and low odor make it convenient to work with, providing a hassle-free experience.

To achieve optimal results, it’s essential to consider factors such as cure time, temperature, and proper mixing techniques. In addition, Liquid Glass Epoxy offers excellent adhesion, ensuring a long-lasting and waterproof seal on your countertops. Whether you’re working on a new countertop installation or refurbishing an existing one, Liquid Glass Epoxy is a versatile and dependable choice for waterproofing countertops effectively.

Waterproofing Basements and Foundations With Liquid Glass Epoxy

Maximize the durability and waterproofing of your basement and foundation with the unmatched performance of Liquid Glass Epoxy. When it comes to protecting these critical areas of your home, Liquid Glass Epoxy is the ideal solution. Here are four reasons why:

- Deep Pour Capability: Liquid Glass Epoxy can be poured between 2-4 inches, providing unmatched industry performance and convenience. With this deep pour capability, you can eliminate the need for multiple pours and save valuable time and effort.

- Bubble-Free Finish: The low-viscosity formulation of Liquid Glass Epoxy allows air bubbles to rise to the surface, ensuring a bubble-free and crystal-clear finish. This not only enhances the aesthetic appeal but also ensures long-lasting waterproofing protection.

- Excellent Adhesion: Liquid Glass Epoxy offers excellent adhesion to various surfaces, including basements and foundations. It forms a strong bond that resists water penetration, ensuring maximum waterproofing effectiveness.

- Quick Cure Time: Liquid Glass Epoxy has a quick cure time, allowing for faster completion of your waterproofing project. You can enjoy the benefits of a waterproof basement and foundation in less time, minimizing disruptions to your daily life.

With Liquid Glass Epoxy, you can trust that your basements and foundations will be protected from water damage for years to come. Its superior performance, deep pour capability, bubble-free finish, excellent adhesion, and quick cure time make it the perfect choice for your waterproofing needs.

Waterproofing Roofs and Gutters With Liquid Glass Epoxy

Liquid Glass Epoxy offers exceptional performance for waterproofing roofs and gutters, extending beyond basements and foundations. It provides a reliable solution that ensures a strong and resilient surface. One of its key advantages is the ability to be used for deep pour applications, with pours between 2-4 inches thick easily achieved using the SuperClear® Liquid Glass® Deep Pour Epoxy. This makes it ideal for thicker applications like roofs and gutters.

The low-viscosity formulation of Liquid Glass Epoxy allows bubbles to effortlessly rise to the surface, resulting in a bubble-free and crystal-clear finish. This not only enhances the visual appeal of the surface but also ensures a seamless and effective waterproofing solution.

Furthermore, Liquid Glass Epoxy offers excellent adhesion to various surfaces, including roofs and gutters. This ensures that the epoxy forms a strong bond with the surface, enhancing its waterproofing capabilities.

In terms of curing, Liquid Glass Epoxy is designed to cure at room temperature, making it convenient and easy to work with. The curing process is reliable and predictable, ensuring a consistent and durable waterproofing solution.

Maintenance and Longevity of Liquid Glass Epoxy Waterproofing

To ensure the optimal maintenance and longevity of your Liquid Glass Epoxy waterproofing, it’s crucial to follow proper care guidelines and regularly inspect the treated surfaces. Here are four important steps to help you maintain the surface and maximize the lifespan of your liquid glass epoxy waterproofing:

- Clean the surface: Keep the treated surface clean by removing any dirt, debris, or stains promptly. Use a mild detergent and a soft cloth or sponge to clean the surface gently. Avoid abrasive cleaners or scrub brushes that may damage the epoxy coating.

- Avoid sharp objects: Liquid Glass Epoxy provides excellent resistance to scratches and impacts, but it’s still important to avoid dragging sharp objects or heavy items across the surface. Use protective mats or felt pads under furniture legs and take care when handling tools or equipment.

- Regular inspections: Periodically inspect the treated surface for any signs of damage, such as cracks, chips, or peeling. Address any issues promptly to prevent further damage and maintain the integrity of the waterproofing.

- Reapply as needed: Over time, the liquid glass epoxy coating may wear down due to exposure to UV rays, chemicals, or heavy usage. If you notice any areas with reduced waterproofing properties or signs of wear, consider reapplying a fresh coat of liquid glass epoxy to ensure continued protection.

Frequently Asked Questions

Is Liquid Glass the Same as Epoxy?

Yes, liquid glass is a type of epoxy. However, while they share similarities, they are not the same product. It’s important to consider their characteristics carefully and recommended uses before choosing one for your project.

How Long Does Liquid Glass Epoxy Take to Harden?

Liquid Glass Epoxy typically hardens within 12-24 hours and fully cures in 48-72 hours. Factors like temperature and humidity can affect the hardening process. To accelerate curing, stir for 5 minutes, use a heat gun, or contact the manufacturer for support.

Is Epoxy Good for Waterproofing?

Epoxy is an excellent choice for waterproofing due to its durability and long-lasting performance. Compared to other methods, it offers a reliable solution with a crystal-clear finish. Common applications include countertops and river tables. However, it’s important to consider the cost and potential drawbacks. Expert opinions vary on its effectiveness.

How Do You Use Liquid Glass Epoxy?

To use liquid glass epoxy, start by preparing the surface and mixing the epoxy with the correct ratios. Apply it using application techniques, allowing it to cure and dry. Enjoy the benefits of its coverage, suitability, layering options, and easy cleaning.

Conclusion

In conclusion, liquid glass epoxy offers a superior solution for waterproofing various surfaces. Its deep pour capabilities and bubble-less technology make it a convenient and reliable choice for artists and woodworkers.

Whether it’s countertops, river tables, or artwork, the crystal clear finish and exceptional durability of liquid glass epoxy ensure long-lasting performance. Like a protective shield, this waterproofing solution creates a seamless barrier, safeguarding against water damage and extending the lifespan of the treated surfaces.

Trust in the clarity and ease of use of liquid glass epoxy for your waterproofing needs.