Are you looking for a versatile and durable solution for your next project? Look no further than liquid glass epoxy.

This innovative material has revolutionized the world of design and construction with its endless possibilities. From stunning countertops and tabletops to waterproofing and sealing applications, liquid glass epoxy offers a crystal-clear finish and exceptional durability.

But that’s not all. Stay tuned to discover the many innovative uses of this remarkable material and unlock a whole new level of creativity in your projects.

Key Takeaways

- Liquid Glass Epoxy offers a variety of applications, including countertop and tabletop designs, flooring solutions, and seamless and hygienic surfaces.

- It has properties such as creating a protective barrier, preventing water and moisture penetration, and self-leveling to eliminate soft spots or tacky areas.

- In industrial and commercial settings, it has deep pour capability for countertops and river tables, bubble-less technology for a smooth surface, and compatibility with pigments for customized designs.

- Liquid Glass Epoxy can be used in innovative furniture designs, providing a crystal clear finish for unique table designs, durability for visually stunning chairs, and the ability to harden soft surfaces for scratch and stain resistance. Additionally, it can create ambient temperature effects for color-changing tables.

Countertop and Tabletop Designs

Liquid Glass Epoxy is a versatile and high-performing solution for creating stunning countertops and tabletop designs. With its low-viscosity formulation, it allows for easy pouring and eliminates the need for multiple pours. The Superclear® Liquid Glass® Deep Pour Epoxy can be poured between 2-4 inches, providing convenience and unmatched performance by reducing 75% of work. This deep pour capability is ideal for creating river tables, charcuterie boards, and even floral arrangements.

One of the key advantages of Liquid Glass Epoxy is its ability to produce a bubble-free and crystal-clear finish. The epoxy’s low viscosity allows bubbles to rise to the surface as it cures, ensuring a smooth and flawless result without the need for additional steps to remove bubbles. This saves time and effort, making the process more efficient.

To achieve the best results with Liquid Glass Epoxy, it’s recommended to use a seal coat before pouring the deep-pour epoxy. This helps to ensure proper adhesion and prevents any potential issues. Additionally, a heat gun can be used to remove any remaining bubbles after pouring, and isopropyl alcohol can be used to clean the surface and remove any contaminants.

Flooring Solutions

When it comes to flooring solutions, Liquid Glass Epoxy offers durability and long-lasting performance. Its seamless and hygienic finish makes it an ideal choice for various applications.

Additionally, the versatility of Liquid Glass Epoxy provides endless design options, allowing you to create unique and visually stunning floors.

Durable and Long-Lasting

To ensure a durable and long-lasting flooring solution, consider utilizing the exceptional performance and convenience of Superclear® Liquid Glass® Deep Pour Epoxy. This product offers a deep pour capability of 2-4 inches, eliminating 75% of work and saving you valuable time.

Liquid Glass® Epoxy is a low-viscosity formulation that effortlessly allows bubbles to rise to the surface as it cures, resulting in a bubble-free and crystal-clear finish. This eliminates the need for additional steps to remove bubbles, making the process more efficient. By using Liquid Glass® Deep Pour Epoxy, you can prevent air bubbles from forming on the surface, ensuring a smooth and flawless finish.

Its thick consistency and high-quality manufacturing standards make it the perfect choice for high-traffic areas. It provides exceptional durability that can withstand years of wear and tear—Trust Liquid Glass® Deep Pour Epoxy for a long-lasting and durable flooring solution.

Seamless and Hygienic

For a flooring solution that not only ensures durability and longevity but also provides a seamless and hygienic surface, consider the exceptional performance and convenience of Superclear® Liquid Glass® Deep Pour Epoxy.

This liquid glass epoxy offers a non-porous and seamless surface, eliminating grout lines and joints where dirt and bacteria can accumulate. The surface is resistant to moisture, stains, and bacterial growth, making it ideal for areas requiring high levels of hygiene.

To ensure a proper application, it’s important to mix the epoxy thoroughly and scrape the sides of the container. The surface should be cleaned and prepped before pouring the deep-pour epoxy. Once poured, allow the epoxy to fully cure before lightly sanding the surface and applying a seal coat.

The seamless and hygienic properties of liquid glass epoxy make it an excellent choice for areas that demand cleanliness and easy maintenance.

Versatile Design Options

Liquid Glass Epoxy offers a wide range of versatile design options for flooring solutions. With its deep pour capability of 2-4 inches, this epoxy resin is perfect for creating unique and stunning wood floors.

Before pouring, make sure your surface is clean and free of any debris by wiping it with Isopropyl Alcohol. Once prepared, pour the Liquid Glass Epoxy onto the surface and spread it evenly using a brush or roller.

Allow sufficient time for the epoxy to fully cure before applying a second coat or seal coat. The bubble-less technology of Liquid Glass Epoxy ensures a flawless and crystal-clear finish, eliminating the need for additional steps to remove bubbles.

With its high-quality manufacturing standards and reliable technical support, Liquid Glass Epoxy is the ideal choice for achieving versatile and beautiful flooring designs.

Creative Resin Art Projects

If you’re looking to unleash your creativity and explore the world of resin art, Liquid Glass® Epoxy offers a high-quality and versatile solution. Whether you’re a seasoned artist or just starting, working with epoxy can open up a world of possibilities for your resin art projects.

One of the key benefits of using Liquid Glass® Epoxy for resin art is its ability to create a crystal clear, bubble-free finish. The low-viscosity formulation allows bubbles to rise to the surface as the epoxy cures, ensuring a flawless result. This is particularly important when working on intricate designs or when trying to achieve a smooth, glass-like appearance.

When working with Liquid Glass® Epoxy for resin art projects, it’s important to apply multiple coats to ensure the best possible outcome. The recommended approach is to pour a thin seal coat first, allowing it to fully cure before adding another layer. The number of layers you’ll need to apply may vary depending on the desired thickness and depth of your artwork.

For projects that require a deeper pour, such as live edge epoxy or larger resin art pieces, Liquid Glass® Deep Pour Epoxy is highly recommended. With its ability to be poured between 2-4 inches, this epoxy eliminates the need for multiple pours and provides a clear finish that’s second to none.

Protective Coatings for Electronics

A reliable and durable protective coating is essential to protect and enhance the performance of electronic devices. Liquid Glass® Deep Pour Epoxy offers a solution that provides superior protection while maintaining the clarity required for electronic displays. When applying the epoxy as a protective coating for electronics, it’s important to follow the proper mixing and application instructions to ensure optimal results.

Here is a step-by-step guide to applying Liquid Glass® Deep Pour Epoxy as a protective coating for electronics:

- Prepare the epoxy mixture:

Measure the epoxy and hardener in a dry bucket or cup, following all mixing directions provided by the manufacturer.

- Mix the epoxy thoroughly:

Use a mixing stick to blend the epoxy components until they’re well combined. Make sure to scrape the sides and bottom of the container to ensure complete mixing.

- Apply the seal coat:

Use a brush or roller to apply a thin seal coat to the surface of the electronics. This will help to ensure proper adhesion and protect against any potential leaks or damage.

- Remove any bubbles:

After applying the seal coat, use a heat gun or torch to remove any bubbles that may have formed carefully. Gently sweep the heat source back and forth over the surface, allowing the bubbles to rise and pop.

Waterproofing and Sealing Applications

When applying Liquid Glass® Deep Pour Epoxy as a protective coating for electronics, it’s crucial to ensure proper waterproofing and sealing to maintain the integrity and performance of the devices. Liquid Glass Epoxy provides an innovative solution for waterproofing and sealing applications due to its unique properties and versatility.

Liquid Glass Epoxy is a pourable epoxy resin that, when mixed and poured onto surfaces, hardens to create a protective barrier. This barrier prevents water and moisture from penetrating the surface, protecting the electronics from potential damage. The epoxy forms a durable, waterproof seal that keeps the devices safe and secure.

One of the key advantages of Liquid Glass Epoxy is its ability to self-level and eliminate soft spots or tacky areas. This ensures an even and consistent coating, enhancing the waterproofing and sealing capabilities. The low viscosity of the epoxy allows it to penetrate small crevices and gaps, ensuring complete coverage and protection.

Liquid Glass Epoxy also offers excellent adhesion to various materials, including metals, plastics, and ceramics. This makes it suitable for a wide range of electronic devices, regardless of their composition. Whether it’s sealing circuit boards or protecting sensitive components, Liquid Glass Epoxy provides a reliable and durable solution.

Industrial and Commercial Applications

Liquid Glass Epoxy is highly versatile and finds extensive use in various industrial and commercial applications due to its exceptional properties and capabilities. Here are five key reasons why this epoxy is widely used in these sectors:

- Deep Pour Capability: SuperClear® Liquid Glass® Deep Pour Epoxy allows for thick pours of 2-4 inches, making it ideal for industrial applications such as creating durable countertops and river tables. Its ability to handle deep pours sets it apart from other epoxies in the market.

- Bubble-less Technology: The epoxy offers bubble-less technology, ensuring a smooth and flawless surface without the need for additional steps to remove bubbles. This feature saves time and effort, providing a high-quality finish for commercial projects.

- Made in the USA: Liquid Glass® Deep Pour Epoxy is proudly made 100% in the USA, adhering to high-quality manufacturing standards. By supporting the local economy and jobs, you can feel confident in the reliability and consistency of this epoxy.

- Single-Pour Convenience: The kit size and convenience of this epoxy eliminate the need for multiple pours, saving time and effort. Whether you’re working on a small repair or a large desk pour, this epoxy allows you to achieve your desired results with ease.

- Compatibility with Pigments: This epoxy is compatible with various pigments, allowing you to create unique and customized designs for your industrial or commercial projects. The versatility of the epoxy opens up a world of possibilities for creative expression.

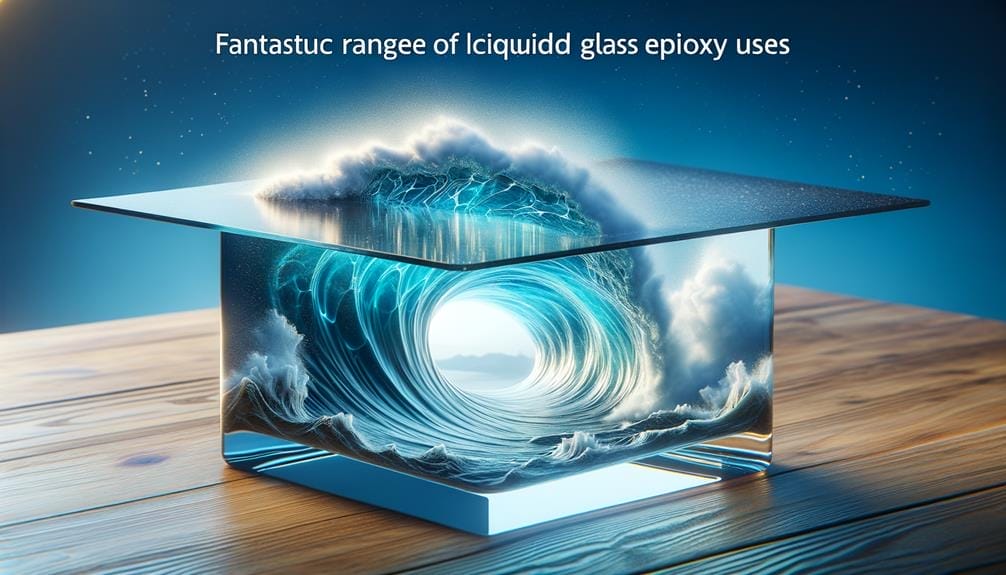

Innovative Furniture Designs

Now, let’s explore the exciting world of innovative furniture designs that can be achieved with Liquid Glass® Deep Pour Epoxy.

With its crystal clear finish and bubble-free formulation, this epoxy is perfect for creating unique table designs that will captivate any space.

Additionally, the versatility of Liquid Glass® Resin allows for creative chair concepts, providing durability and a long-lasting finish for furniture that’s both functional and visually stunning.

Unique Table Designs

With its deep pour capabilities and crystal clear finish, Liquid Glass® Epoxy is an ideal choice for creating unique and innovative table designs. Here are some ways you can use Liquid Glass® Epoxy to create stunning tables:

- Pouring weights: Liquid Glass® Epoxy can be used to create tables with embedded weights, giving them a sleek and modern look.

- Harden soft surfaces: By applying Liquid Glass® Epoxy to soft surfaces like wood or fabric, you can create a durable and beautiful table that’s resistant to scratches and stains.

- Ambient temperature effects: Liquid Glass® Epoxy can be used to capture the beauty of ambient temperature changes, creating tables that change color or pattern with the environment.

- Small-scale designs: Liquid Glass® Epoxy allows you to create intricate and detailed designs on small-scale tables, adding a touch of elegance to any space.

- Deep pour effects: With its deep pour capabilities, Liquid Glass® Epoxy enables you to create tables with mesmerizing depth and dimension, making them the focal point of any room.

Creative Chair Concepts

To explore innovative furniture designs after discussing unique table concepts, let’s now delve into the realm of creative chair concepts.

Liquid Glass Epoxy can be utilized in the creation of unique and durable chairs. When pouring the epoxy, it’s important to consider the appropriate pour depth to ensure structural integrity. Adding weights or clamps during the curing process can help prevent any potential warping or bending. It’s crucial to allow the epoxy to fully harden before removing any weights or clamps to avoid creating soft spots.

Additionally, ambient temperature can affect the curing process, so it’s important to work in a controlled environment. Smaller-scale chair designs can be achieved by using molds or forms. Once hardened, any rough or uneven areas can be sanded down using sandpaper.

The deep pour capabilities of Liquid Glass Epoxy allow for the creation of chairs that are both visually appealing and functional, as they can withstand weight and flex without compromising their structural integrity.

Unique Lighting Fixtures

Unique lighting fixtures can be created using Liquid Glass® Deep Pour Epoxy, which offers unmatched industry performance and a crystal-clear finish in thicknesses of 2-4 inches. This innovative epoxy is perfect for producing stunning lighting fixtures that are both functional and visually appealing. Here are five reasons why Liquid Glass® Deep Pour Epoxy is the ideal choice for your unique lighting fixtures:

- Easy pour: The low viscosity of Liquid Glass® Epoxy makes it effortless to pour into molds, ensuring a smooth and even application.

- Lightweight: Liquid Glass® Epoxy is lightweight, making it perfect for creating lighting fixtures that can be easily hung or mounted.

- Quick hardening: Liquid Glass® Epoxy has a quick curing time, allowing your lighting fixtures to be ready for use in no time.

- Soft ambient temperature: The epoxy cures at a soft ambient temperature, ensuring that the heat generated during the curing process doesn’t damage the fixture.

- Flexibility: Liquid Glass® Epoxy is highly flexible, allowing you to create lighting fixtures in various shapes and designs.

With Liquid Glass® Deep Pour Epoxy, you can bring your unique lighting fixture ideas to life. Its deep pour capability, ease of use, and exceptional clarity make it the perfect choice for creating one-of-a-kind lighting fixtures that will enhance any space.

Architectural and Interior Design Elements

Liquid Glass® Deep Pour Epoxy isn’t only perfect for creating unique lighting fixtures but also offers exceptional versatility for architectural and interior design elements. This epoxy can be poured anywhere between 2-4 inches, making it ideal for a wide range of applications such as countertops and river tables. Its low-viscosity formulation effortlessly allows bubbles to rise to the surface as it cures, ensuring a bubble-free and crystal-clear finish.

When working on architectural and interior design projects, Liquid Glass® Deep Pour Epoxy provides unmatched convenience. Its ability to be poured in a single pour eliminates the need for multiple pours, saving you time and effort. Additionally, its clear finish allows for easy calculation of epoxy pour volume, ensuring that you have enough material for your project.

To further enhance your design, Liquid Glass® Deep Pour Epoxy can be used on various surfaces such as wood panels or good-quality canvas. It offers a smooth and glossy finish with complete UV stability, ensuring that your design will remain vibrant and beautiful for years to come.

Incorporating Liquid Glass® Deep Pour Epoxy into your architectural and interior design elements is simple. First, prepare your mold or surface by cleaning it thoroughly and ensuring it’s free of any dust or debris. Then, mix the epoxy according to the manufacturer’s instructions and pour it onto the desired surface. Use a spreader or brush to distribute the epoxy evenly and remove any air bubbles evenly. Finally, allow the epoxy to harden and cure, following the recommended curing time provided by the manufacturer.

With Liquid Glass® Deep Pour Epoxy, you can confidently create stunning and durable architectural and interior design elements that will leave a lasting impression. So go ahead and let your creativity flow with this versatile epoxy.

Sustainable and Eco-Friendly Building Materials

You can explore green construction alternatives and environmentally friendly solutions with Liquid Glass Epoxy.

This sustainable building option offers a crystal-clear finish for various applications while also being kind to the environment.

Green Construction Alternatives

Sustainable and eco-friendly building materials play a crucial role in reducing environmental impact and promoting a healthier planet. When considering green construction alternatives, here are some options to consider:

- Reclaimed wood: Using salvaged wood helps reduce deforestation and waste while adding character and uniqueness to your project.

- Recycled metal: Utilizing recycled metal reduces the need for mining and conserves natural resources.

- Bamboo: A fast-growing grass, bamboo is a sustainable alternative to traditional timber, known for its strength and versatility.

- Straw bales: These bales are an excellent choice for insulation and can be sourced from agricultural byproducts.

- Hempcrete: Made from hemp fibers and lime, hempcrete is a carbon-negative material that provides excellent insulation and breathability.

Incorporating these materials into your construction projects not only supports sustainable development but also contributes to a greener and healthier future.

Environmentally Friendly Solutions

Environmentally friendly solutions for sustainable and eco-friendly building materials encompass a wide range of options that support green construction practices.

Liquid Glass Epoxy is an excellent choice for builders looking to reduce their environmental impact. This epoxy can be poured into molds of various shapes and sizes, allowing for flexibility in design. It weighs less than traditional building materials, making it easier to transport and handle.

Liquid Glass Epoxy also hardens at ambient temperatures, eliminating the need for excessive energy consumption during the curing process. Additionally, this epoxy is made from renewable resources, further contributing to sustainable construction practices. Its durability and long-lasting properties also reduce waste, making it an ideal choice for environmentally conscious builders.

With Liquid Glass Epoxy, you can create sustainable and eco-friendly buildings on a small scale or in deep construction projects while still providing the flexibility and strength needed.

Sustainable Building Options

Liquid Glass Epoxy offers builders a sustainable and eco-friendly option for their construction projects. Here are five reasons why this material is a great choice for sustainable building:

- Reduced Environmental Impact: By using Liquid Glass Epoxy, you contribute to the promotion of sustainability. This material is made in the USA, supporting the local economy and manufacturing standards.

- Long-Lasting Durability: Liquid Glass Epoxy provides exceptional durability and reliability, reducing the need for frequent replacements. This minimizes waste and extends the lifespan of your construction projects.

- Versatile Applications: Whether you’re working on countertops or river tables, Liquid Glass Epoxy can be used for a wide range of sustainable building projects. Its versatility contributes to eco-friendly designs.

- Renewable and Eco-Friendly: Liquid Glass Epoxy is a sustainable option that offers a durable, long-lasting finish. It’s designed to have minimal environmental impact, making it an eco-friendly choice.

- Ambient Temperature Flexibility: This epoxy can be poured and used at ambient temperatures, allowing for easy application. Its soft initial state allows for easy manipulation, and it hardens to a deep, strong finish.

Artistic and Decorative Installations

For artistic and decorative installations, Liquid Glass Epoxy offers a deep pour capability of 2-4 inches, allowing for a crystal clear finish and unparalleled structural integrity. This feature makes it an excellent choice for creating stunning countertops, river tables, and artwork. When using Liquid Glass Epoxy for these installations, it’s crucial to pour in layers of the recommended thickness to achieve optimal results.

To ensure the epoxy cures properly, it’s important to pour in layers that are thick enough to maintain their shape and not slump or sag. Pouring too thin of a layer can result in soft spots and compromised structural integrity. It’s recommended to pour in layers that are at least 1/4 inch thick.

As the epoxy cures, it will begin to harden within the first few hours. It’s essential to monitor the curing process and add weights if necessary to prevent the epoxy from flowing or self-leveling too much. Adding enough weights to keep the epoxy in place will help maintain the desired shape and prevent any unwanted distortion.

To achieve the best results, it’s crucial to pour additional layers once the previous layer has reached a certain level of hardness. It’s generally recommended to wait until the epoxy has reached 70-80 degrees Fahrenheit before adding additional layers. This will ensure proper bonding and minimize the risk of delamination.

When working with Liquid Glass Epoxy for artistic and decorative installations, it’s beneficial to practice on a smaller scale to understand its behavior and the timing of each layer’s curing process. This will help you gain confidence and achieve the desired outcome for your larger projects.

Frequently Asked Questions

What Is Glass Epoxy Used For?

Glass epoxy is used to enhance the durability of wooden furniture, repair, and waterproof electronic devices, and explore possibilities in jewelry making. It also plays a role in automotive manufacturing, the aerospace industry, and construction innovations.

What Is the Difference Between Epoxy Resin and Liquid Glass?

Liquid glass epoxy is a game-changer. Its thicker pours and bubble-free finish make it superior to regular epoxy resin. Plus, its UV stability keeps your art looking vibrant. Say goodbye to multiple pours and hello to convenience!

How Do You Use Liquid Glass Epoxy?

To use liquid glass epoxy, start by preparing your workspace and gathering the necessary tools. Follow a step-by-step guide incorporating top tips and tricks for creative applications. Avoid common mistakes, choose the best brands, and take safety precautions. Enhance durability with proper mixing and finishing techniques.

How Long Does Liquid Glass Epoxy Take to Harden?

Liquid glass epoxy typically takes around 24 hours to harden, but factors like temperature, humidity, and thickness can affect curing time. To speed up hardening, ensure proper mixing and use a heat gun. Testing for full hardening can be done by pressing your fingernail into the surface.

Conclusion

In conclusion, liquid glass epoxy is a versatile and reliable solution for a wide range of projects. It can be used for countertops, artwork, and protective coatings. Its deep pour capabilities and bubble-less technology ensure a crystal-clear finish and exceptional durability. Liquid glass epoxy is a convenient and time-saving option, as it is made in the USA and can be used both indoors and outdoors. It is like a chameleon, adapting to various applications, making it an innovative and valuable choice for any project.