When it comes to epoxy resin, it’s like stepping into a vast ocean with countless types to explore. Each resin type has its unique properties and applications, making it crucial to understand the differences between them.

From the versatile Bisphenol Epoxy Resins to the specialized Halogenated Epoxy Resins, there is a world of possibilities waiting to be uncovered. So, let’s dive in and discover the various epoxy resin types that can bring your projects to life.

Key Takeaways

- Epoxy resin types are categorized based on chemical processes and characteristics, including casting resin for molds and castings and deep pour epoxy resin for thick layers.

- Bisphenol epoxy resins offer exceptional heat resistance, mechanical strength, and chemical stability, making them widely used in aerospace, electronics, and automotive sectors.

- Aliphatic epoxy resins have exceptional color and UV stability, low viscosity, and high glass transition temperature, making them commonly used in automotive, aerospace, and marine industries.

- Other types of epoxy resins include novolac epoxy resins with outstanding heat resistance, halogenated epoxy resins with improved flame retardancy, epoxy resin diluents that control viscosity and flow, and glycidylamine epoxy resins with strong adhesive properties.

Epoxy Resin Types Explained

When exploring epoxy resin types, it’s important to understand the distinctions between different categories and their unique properties and applications. Epoxy resin can be categorized based on its chemical process and characteristics.

One common type is casting resin, which is specifically formulated for creating molds and castings. It has a low viscosity, allowing it to flow easily into intricate molds and capture fine details.

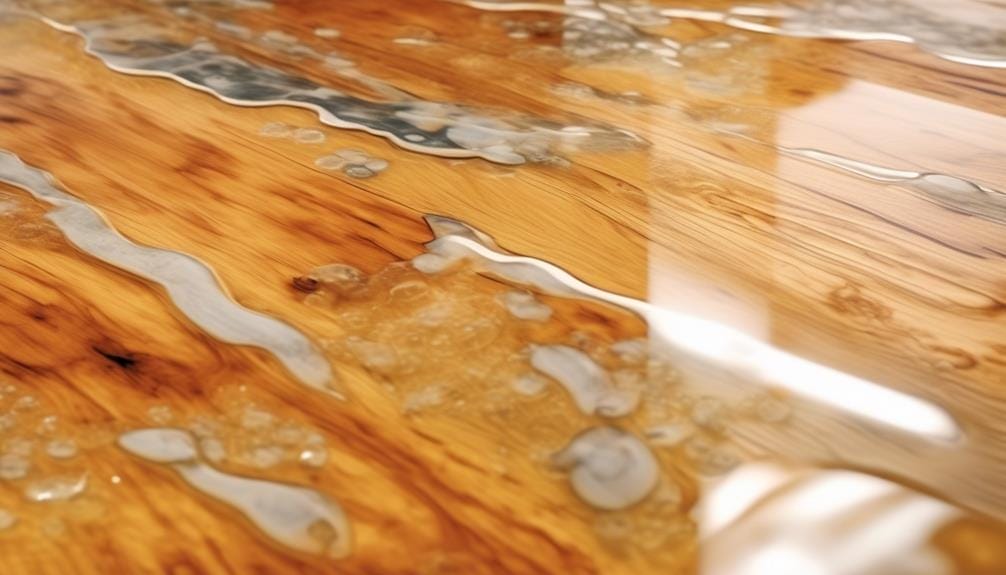

Another type is deep-pour epoxy resin, which is designed for pouring thick layers at once. It has a high viscosity, preventing excessive heat buildup during the curing process. This type is commonly used for creating river tables and countertops.

Epoxy resins also vary in their reaction and performance. Some resins have a fast curing time, allowing for quick turnaround in production processes. Others have a slower reaction time, which is beneficial when working on large-scale projects or when additional time is needed for adjustments.

Additionally, there’s a wide range of epoxy resin types available, each with specific uses and properties. Aliphatic epoxy resins offer excellent UV resistance and are often used in outdoor applications. Cycloaliphatic epoxy resins provide enhanced chemical resistance and are suitable for industrial environments. Bisphenol epoxy resins are commonly used for general-purpose applications, while Novolac epoxy resins offer excellent chemical resistance and high-temperature resistance. Lastly, Glycidylamine epoxy resins are known for their superior toughness and adhesion.

Understanding the different epoxy resin types is crucial for selecting the right one for your specific application. Whether you need a resin with low viscosity for intricate molds or high viscosity for thick pours, there’s a type of epoxy resin available to suit your needs. By considering the unique properties and applications of each epoxy resin type, you can ensure optimal results in your projects.

Bisphenol Epoxy Resins

Bisphenol epoxy resins offer a range of benefits that make them highly desirable in various industries. These resins are known for their exceptional heat resistance, mechanical strength, and chemical stability. As a result, they find extensive applications in the aerospace, electronics, and automotive sectors.

Their outstanding performance characteristics, including durability, corrosion resistance, and electrical insulation properties, make them a preferred choice for producing composite materials, adhesives, coatings, and electrical components.

Benefits of Bisphenol Epoxy

Bisphenol epoxy resins exhibit exceptional adhesion to a wide range of surfaces, making them highly advantageous for various demanding applications. This type of epoxy resin is formulated through a chemical reaction between bisphenol A and epichlorohydrin.

The resulting resin is a versatile and widely used material that provides high strength and durability. It’s resistant to heat, chemicals, and moisture, ensuring its suitability for applications that require excellent performance under harsh conditions.

Bisphenol epoxy resins can also be easily modified with additives to enhance specific properties, further expanding their range of applications. Industries such as construction, automotive, electronics, aerospace, and arts commonly rely on bisphenol epoxy resins for coatings, adhesives, composites, and artistic creations.

Their exceptional adhesion and strength make them an ideal choice for various demanding and high-performance applications.

Applications of Bisphenol Epoxy

With its exceptional adhesion and strength, bisphenol epoxy resin finds extensive applications in various demanding industries, showcasing its versatility and reliability. Some of the key applications of bisphenol epoxy resin include:

- Electrical insulation: Bisphenol epoxy resins are commonly used in the electrical industry due to their high levels of electrical insulation. They protect components from short-circuiting caused by dust and moisture.

- Manufacturing and construction: These resins are used in the production of molds, laminates, castings, and fixtures. They’ve replaced traditional materials like metal and wood, offering efficiency and cost reduction.

- Structural adhesives: Epoxy resin adhesives, a type of bisphenol epoxy resin, are widely used in aerospace, sports equipment, and construction. They provide strong bonding properties for structural applications.

In addition to these applications, bisphenol epoxy resins are also utilized for repairing, bonding, and filling gaps. Their moldable form as epoxy putty allows for easy shaping and molding, providing a strong and durable bond once cured.

Aliphatic Epoxy Resins

Now, let’s explore the benefits of aliphatic epoxy resins and their wide range of applications.

These resins offer exceptional color and UV stability, making them ideal for outdoor coatings that require long-term color retention.

Additionally, their low viscosity and high glass transition temperature provide excellent weather resistance and durability.

From outdoor flooring to decorative coatings and protective topcoats, aliphatic epoxy resins are a reliable choice for applications that demand both performance and aesthetic appeal.

Benefits of Aliphatic Epoxy

Aliphatic epoxy resins exhibit exceptional UV resistance, making them an ideal choice for outdoor applications where color retention and durability are paramount. These resins offer numerous benefits, including:

- Superior color stability: Aliphatic epoxy resins don’t yellow or degrade when exposed to sunlight, ensuring long-lasting aesthetics in decorative and aesthetic applications.

- Excellent chemical resistance: These resins can withstand harsh chemicals and cleaning agents, making them suitable for environments with high chemical exposure.

- Improved weathering and aging properties: Aliphatic epoxy resins have enhanced durability, allowing them to withstand outdoor conditions and environmental exposure over extended periods.

Due to their exceptional UV resistance and performance characteristics, aliphatic epoxy resins find extensive use in industries such as automotive, aerospace, and marine.

When it comes to outdoor applications that demand color retention and durability, aliphatic epoxy resins are the go-to choice.

Applications of Aliphatic Epoxy

When considering the wide range of applications for aliphatic epoxy resins, their exceptional UV resistance and color stability make them a popular choice for various industries. These resins are commonly used as protective coatings in outdoor environments, such as automotive topcoats and decorative finishes, where maintaining color and gloss over time is crucial.

They’re also suitable for industrial flooring and chemical containment due to their high level of chemical resistance. In marine and aerospace applications, aliphatic epoxy resins are preferred because they can withstand harsh environmental conditions and UV radiation.

Additionally, these resins are ideal for architectural and decorative concrete coatings, as they can maintain color and gloss in outdoor environments. The mechanical properties and low dielectric constants of aliphatic epoxy resins make them well-suited for casting resins and industrial grades.

Some specific types of aliphatic epoxy resins include Novolac Epoxy and Glycidylamine Epoxy. Overall, their exceptional UV resistance, color stability, and mechanical properties make aliphatic epoxy resins versatile and reliable for a wide range of applications in various industries.

Novolac Epoxy Resins

Novolac epoxy resins, renowned for their outstanding heat resistance and exceptional chemical resilience, are highly sought-after in industries requiring superior performance under harsh conditions. These specialized resins offer a range of benefits that make them ideal for demanding applications:

- Extreme Chemical Resistance: Novolac epoxy resins are specifically designed to provide strong resistance against a wide range of chemicals. This makes them suitable for use in critical industrial settings where exposure to corrosive substances is common.

- High-Temperature Applications: With their enhanced functionality, novolac epoxy resins are particularly well-suited for high-temperature environments. They can withstand extreme heat without losing their structural integrity, ensuring reliable performance even under challenging conditions.

- Low VOCs and Solvent-Free: Novolac epoxy resins are preferred in applications where the use of volatile organic compounds (VOCs) or solvents is undesirable. These resins offer a solvent-free alternative, making them environmentally friendly and reducing potential health hazards.

The curing process of novolac epoxy resins involves the reaction between epoxy and a curing agent, resulting in a highly cross-linked and durable material. The aliphatic structure of these resins contributes to their exceptional chemical resistance and thermal stability, making them a top choice for industries such as aerospace, automotive, and chemical manufacturing.

With their ability to withstand harsh conditions and provide long-lasting performance, novolac epoxy resins continue to be in high demand.

Halogenated Epoxy Resins

Halogenated epoxy resins are derived from the reaction between epoxy compounds and halogenated compounds, resulting in improved flame retardancy and resistance to chemicals and solvents. These types of epoxy resins are commonly used in the electronics industry, particularly for printed circuit boards and electrical components. The addition of halogen atoms enhances the performance of epoxy resins in environments with stringent fire safety requirements.

One of the key advantages of halogenated epoxy resins is their ability to exhibit improved flame retardancy compared to non-halogenated resins. This is particularly important in applications where fire safety is a critical concern. Halogenated epoxy resins are known for their low smoke and toxicity emissions during combustion, making them suitable for fire-resistant applications.

In addition to improved flame retardancy, halogenated epoxy resins also offer enhanced resistance to chemicals and solvents. This makes them highly suitable for applications where exposure to corrosive substances or aggressive environments is expected.

Epoxy Resin Diluents

Epoxy resin diluents, derived from aliphatic alcohols or polyols, play a crucial role in controlling the viscosity and flow of epoxy resin formulations. These diluents, which can vary in functionality, like monofunctional or difunctional, are used to modify the viscosity of epoxy resin systems.

Here are three important aspects to consider when using epoxy resin diluents:

- Reducing Viscosity: Epoxy resin diluents can help reduce the overall viscosity of epoxy systems, making them easier to handle and apply. By incorporating diluents into the formulation, the viscosity at room temperature can be adjusted to meet specific application requirements.

- Curing Time: The choice of diluent can impact the curing time of the epoxy resin. Certain diluents can accelerate or retard the curing process, allowing for better control over the time and process of resin curing. This is particularly important in applications where a shorter or longer curing time is desired.

- Final Properties: The use of different epoxy resin diluents can also affect the final properties of the cured epoxy coating. The choice of diluent can influence characteristics such as chemical resistance, mechanical strength, and adhesion properties. Therefore, it’s crucial to select the appropriate diluent to achieve the desired performance and application characteristics.

Understanding the role and impact of epoxy resin diluents is essential for formulating epoxy resin systems that meet specific application requirements in terms of viscosity, curing time, and final properties.

Glycidylamine Epoxy Resins

Glycidylamine epoxy resins, derived from the reaction between epichlorohydrin and aromatic amines, offer a range of low to medium-viscosity options for efficient processing in industrial applications. These epoxy resins are known for their adhesive properties, making them a versatile choice for a wide variety of industrial uses. The specific chemical properties of glycidylamine epoxy resins provide strong bonding capabilities, allowing them to form strong bonds with various substrates.

One of the advantages of glycidylamine epoxy resins is their low to medium viscosity, which makes them suitable for a range of industrial applications. Their viscosity allows for easy processing and efficient application, whether in the form of coatings or adhesives. The low viscosity enables these resins to flow and wet out surfaces, ensuring good coverage and adhesion.

The adhesive properties of glycidylamine epoxy resins make them particularly useful in applications where a balance of viscosity and chemical resistance is required. These resins create strong bonds with different substrates, including metals, plastics, and composites. This versatility makes them suitable for various industries, from automotive and aerospace to electronics and construction.

Mixing Epoxy Resin and Hardener

To ensure proper curing and optimal strength, it’s crucial to mix the epoxy resin and hardener accurately in the correct ratio. Here are some important points to consider when mixing epoxy resin and hardener:

- Resin-to-Hardener Ratio: Measure the resin and hardener in the recommended ratio specified by the manufacturer. Deviating from the mixing ratio can result in incomplete curing or weak mechanical properties.

- Thorough Mixing: Thoroughly mix the resin and hardener in a clean container. Make sure to scrape the sides and bottom of the container to ensure even distribution and complete activation of the epoxy.

- Mixing Time: Follow the manufacturer’s instructions regarding mixing time. Insufficient mixing can lead to inconsistent curing and compromised strength.

- Avoiding Air Bubbles: Stir the resin and hardener slowly and gently to minimize the introduction of air bubbles. If air bubbles do form, consider using a heat gun or torch to remove them before application.

- Pot Life: Mix only the amount of epoxy resin and hardener that can be used within the specified pot life. Once the pot life has passed, the mixture will begin to cure and become unusable.

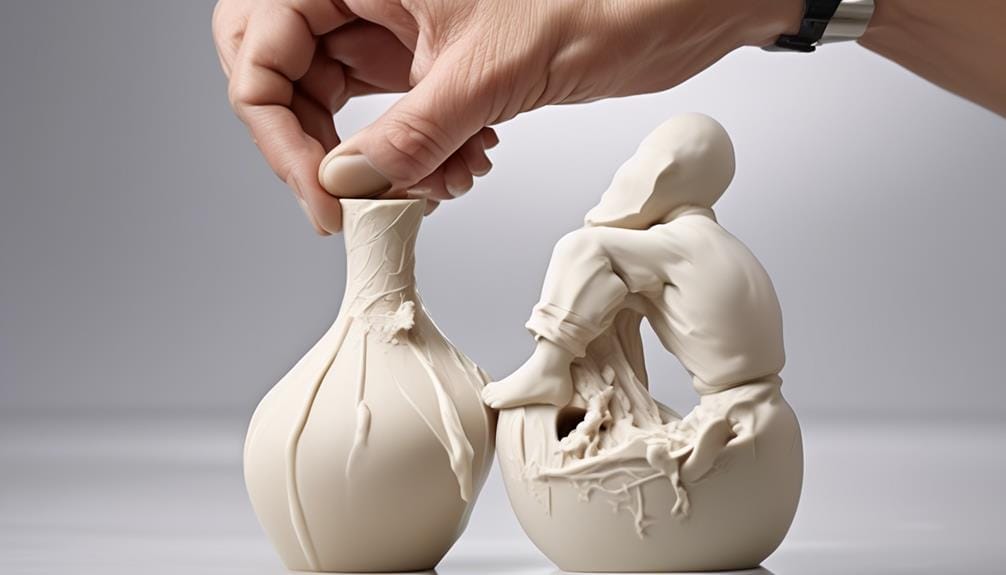

Epoxy Putty

A versatile and moldable form of epoxy resin commonly used for repairing, bonding, and filling gaps is epoxy putty. It is available in different formulations for various applications and can be shaped and molded by hand. Once cured, epoxy putty provides a strong and durable bond, making it ideal for various repair and construction projects. Industries such as manufacturing, construction, aerospace, and sports equipment commonly use epoxy putty for its strong adhesive properties and versatility in various applications.

Epoxy putty is known for its ability to adhere to a wide range of materials, including metals, ceramics, plastics, and wood. It is also resistant to moisture, chemicals, and heat, making it suitable for both indoor and outdoor use. Additionally, epoxy putty has excellent electrical insulation properties, making it suitable for applications that require electrical insulation.

To highlight the different types of epoxy putty and their applications, the following table provides an overview:

| Type of Epoxy Putty | Applications |

|---|---|

| Plastic tooling | Used for creating molds and prototypes in plastic manufacturing processes |

| Electrical insulation | Provides insulation for electrical components and wiring |

| Resin layer | Used for creating a smooth and glossy surface on various materials |

| Synthetic resin | It is ideal for bonding and repairing various materials, including plastics and composites. |

Frequently Asked Questions

Are There Different Kinds of Epoxy Resin?

Yes, there are different kinds of epoxy resin. It is used for various applications such as coatings, adhesives, and composites. It has pros and cons, and proper mixing is important. Avoid common mistakes and follow tips for a glossy finish.

What Are the Three 3 Different Types of Resin?

The three different types of epoxy resin are glycidyl, non-glycidyl, and diluent materials. Each type has distinct properties and is suitable for specific applications. It’s important to choose the right resin and follow safety precautions when working with epoxy.

What Are the Three Types of Epoxy?

The three types of epoxy resin, glycidyl, non-glycidyl, and diluent-based, each have unique properties and applications. Understanding epoxy resin properties is crucial for working with it, including the curing process. Using epoxy resin offers advantages, but safety precautions must be taken.

Which Epoxy Resin Is Best?

To determine the best epoxy resin for your needs, consider factors like application requirements, curing time, and brand reputation. Comparing different brands and understanding their strengths and weaknesses will help you make an informed decision.

Conclusion

In summary, working with epoxy resin requires proper safety measures to avoid any harm or irritation. It’s important to follow instructions, use protective gear, and work in a well-ventilated area.

Different types of epoxy resin, such as bisphenol, aliphatic, novolac, and halogenated, offer varying properties for specific applications. Diluents and glycidylamine epoxy resins also play a role in modifying the resin’s characteristics.

Lastly, proper mixing, application, and curing techniques ensure a smooth and polished result.