Did you know that improper storage and handling of epoxy resin can lead to decreased shelf life and reduced performance? It’s true!

Ensuring the viability of your epoxy resin is crucial for safety and cost efficiency. But don’t worry, we’ve got you covered.

In this discussion, we will explore the importance of proper storage, the factors that affect the resin’s shelf life, and the recommended temperature for storage.

So, let’s dive in and discover how you can extend the shelf life, improve performance, and minimize the risk of crystallization in your epoxy resin.

Key Takeaways

- Proper epoxy resin storage is important to maintain its quality and performance.

- Factors such as temperature, humidity, light exposure, and container seal integrity can affect the shelf life of epoxy resin.

- Recommended storage conditions include maintaining a temperature range of 65 to 90 degrees Fahrenheit, avoiding refrigeration, and storing resin away from heat sources and direct sunlight.

- Moisture prevention, contamination prevention, and safety precautions are essential for effective epoxy resin storage and handling.

Importance of Proper Epoxy Resin Storage

Proper storage of epoxy resin is of utmost importance in ensuring safety, cost efficiency, and the preservation of material viability. Adhering to manufacturer guidelines is essential for safe handling and storage to avoid decreased shelf life, crystallization, or resin performance issues. Storage, ventilation, temperature control, and using suitable containers are critical considerations. Failure to follow these guidelines can lead to resin degradation and compromised performance.

One common mistake in storing epoxy resin is improper sealing. It’s crucial to ensure that containers are tightly sealed to prevent moisture or air from entering, as this can cause the resin to cure prematurely or develop impurities. Another mistake is exposing epoxy resin to direct sunlight. Ultraviolet (UV) radiation can break down the resin molecules, leading to discoloration, reduced strength, and decreased adhesive properties.

Maintaining recommended storage temperatures is also essential. Extreme heat or cold can negatively impact the resin’s shelf life and performance. High temperatures can accelerate the curing process, making the resin unusable, while low temperatures can promote crystallization, resulting in a grainy texture and reduced effectiveness.

Factors Affecting Epoxy Resin Shelf Life

To ensure the maximum shelf life of your epoxy resin, you should carefully consider three key factors:

- Temperature and humidity: Maintaining a stable temperature range of 65°F – 90°F and avoiding extreme temperatures are crucial to preventing crystallization and degradation.

- Exposure to light: Keeping the resin away from direct sunlight will help preserve its quality and viability.

- Container seal integrity: Using properly sealed containers in a dry, dark environment will help preserve the resin’s quality and viability.

Taking these factors into consideration will ensure that your epoxy resin stays in optimal condition for as long as possible.

Temperature and Humidity

Maintaining the recommended temperature range of 65 to 90 degrees Fahrenheit is essential for preserving the viability of epoxy resin. Temperature plays a vital role in the storage stability of epoxy resin. Extreme temperatures can negatively impact the resin’s stability, leading to decreased shelf life and reduced performance. Refrigeration, although commonly used for other materials, does not extend the shelf life of epoxy resin. It is important to store epoxy resin in a dry place with proper ventilation, avoiding heat sources that can cause degradation.

Additionally, tightly sealing containers to prevent air exposure is crucial. Improper storage can result in resin crystallization, discoloration, and premature hardening. By adhering to the recommended temperature range and proper storage guidelines, you can ensure extended shelf life and maintain the quality of your epoxy resin.

| Temperature Range (Fahrenheit) | Viability of Epoxy Resin |

|---|---|

| Below 65 | Decreased |

| 65 – 90 (Recommended) | Stable |

| Above 90 | Decreased |

Exposure to Light

Preserving the viability and quality of epoxy resin involves considering various factors, one of which is the exposure to light. Light can cause degradation in epoxy resin, leading to a reduction in shelf life and compromised performance. UV exposure, in particular, accelerates the degradation process, making it crucial to store epoxy resin in a dark place.

To minimize the effects of light exposure, proper handling and storage practices are essential. Storing epoxy resin in opaque containers and keeping them away from light sources can help prolong its shelf life. Additionally, using UV-resistant packaging can further protect the resin from light-induced degradation.

Shielding epoxy resin from direct sunlight is of utmost importance in maintaining its quality and performance over time. By following proper storage and handling techniques, you can ensure the longevity and effectiveness of epoxy resin.

Container Seal Integrity

Proper container seal integrity is crucial for ensuring the viability and shelf life of epoxy resin. The following factors can significantly affect the shelf life of epoxy resin and highlight the importance of maintaining container seal integrity:

- Temperature: Fluctuations in temperature can cause resin crystallization, leading to reduced performance and potential discoloration or hardening.

- Moisture: Exposure to moisture can compromise the quality of epoxy resin, resulting in decreased effectiveness and potential degradation.

- Air Exposure: Inadequate container sealing allows air to enter, which can accelerate resin oxidation and deterioration.

- Storage Conditions: Proper sealing and storage in dry, cool places, away from direct sunlight, are essential for preserving the integrity of epoxy resin.

To ensure the longevity and performance of epoxy resin, it’s crucial to use containers made of materials compatible with the resin and adhere to manufacturer guidelines for sealing. By maintaining container seal integrity, you can maximize the shelf life and reliability of your epoxy resin.

Recommended Temperature for Epoxy Resin Storage

To ensure optimal storage conditions for epoxy resin, it’s recommended to maintain a temperature range between 65 and 90 degrees Fahrenheit. This temperature range is essential for preserving the quality and performance of the resin.

Refrigeration should be avoided, as it doesn’t prolong the life of the material. Extreme temperatures, both hot and cold, can have a detrimental effect on the shelf life of epoxy resin.

Storing epoxy resin in temperatures below 65 degrees Fahrenheit may cause the material to thicken and become difficult to work with. On the other hand, temperatures above 90 degrees Fahrenheit can accelerate the curing process, reducing the working time and potentially affecting the final outcome of the project.

It is important to store epoxy resin away from heat sources to prevent degradation. Heat can cause premature curing of the material, leading to a shortened shelf life. Direct sunlight and exposure to ultraviolet (UV) radiation should also be avoided, as they can degrade the resin and compromise its performance.

Clean and Dry Storage Conditions for Epoxy Resin

To ensure the quality and performance of epoxy resin, it’s crucial to store it in clean and dry conditions.

Proper storage conditions prevent contamination and moisture absorption, which can negatively affect the resin’s properties and performance.

Proper Storage Conditions

For optimal storage of epoxy resin, ensure that the storage conditions are clean and dry. Proper storage conditions play a crucial role in extending the shelf life of epoxy resin and maintaining its quality. Here are four recommended storage conditions to consider:

- Store in a clean and dust-free environment: Dust or dirt particles can contaminate the resin and affect its performance. Keep the storage area clean and free from any debris.

- Maintain dry conditions: Moisture can cause the resin to cure prematurely or degrade over time. Store epoxy resin in a dry environment to prevent any moisture absorption.

- Control temperature and humidity: Extreme temperatures and high humidity can negatively impact the resin’s stability and shelf life. Keep the storage area at a moderate temperature and humidity level.

- Use sealed containers: To prevent air exposure and moisture absorption, store the epoxy resin in tightly sealed containers. This will help maintain the resin’s integrity and quality over time.

Following these recommended storage conditions will help ensure the longevity and performance of your epoxy resin.

Moisture Prevention

In order to ensure the longevity and performance of your epoxy resin, maintaining clean and dry storage conditions is essential, with moisture prevention being particularly crucial.

Moisture can have a detrimental effect on the storage stability of two-component epoxy resin systems. To prevent moisture from compromising the quality of your epoxy resin, it’s important to store it in a cool and dark place. This will help prevent crystallization and degradation.

Additionally, make sure that the containers used for storing the resin are tightly sealed to prevent air exposure and moisture entry. Storing the resin away from heat sources is also important, as it can prevent premature hardening or curing.

Preventing Contamination in Epoxy Resin Storage

To maintain the integrity of epoxy resin during storage, it’s crucial to implement measures that prevent contamination. Contamination can compromise the quality and performance of epoxy resin, leading to undesirable outcomes in various applications.

Here are four important steps to prevent contamination and ensure the storage stability of epoxy resin:

- Proper sealing: Ensure that epoxy resin containers are tightly sealed to prevent the entry of dust, dirt, and other foreign particles. This can be achieved through the use of airtight lids or caps.

- Clean storage area: Store epoxy resin in a clean and controlled environment to minimize the risk of contamination. Regularly clean the storage area to remove any potential sources of contamination, such as spilled chemicals or debris.

- Avoid cross-contamination: Keep different types of epoxy resin separate to prevent cross-contamination. Store different formulations or grades of epoxy resin in dedicated containers or designated areas to avoid mixing and potential chemical reactions.

- Proper handling: Ensure that storage containers, as well as any tools or equipment used with epoxy resin, are clean and free from contaminants. Use clean, dry utensils to handle epoxy resin and avoid introducing any foreign substances.

Handling Epoxy Resin Safely

To handle epoxy resin safely, it’s crucial to follow proper safety precautions.

Always wear protective gear like safety glasses, gloves, and masks to minimize direct contact and prevent inhalation of fumes.

Additionally, ensure that the resin is stored correctly in a cool, dark place within the recommended temperature range and in suitable containers to prevent degradation and common storage mistakes.

Proper handling and storage techniques not only promote safety but also extend the shelf life and enhance the performance of epoxy resin.

Safety Precautions for Handling Epoxy Resin

When handling epoxy resin, it’s crucial to follow safety precautions to minimize direct contact and exposure. To ensure your safety, consider the following precautions:

- Use protective gear: Wear safety glasses, gloves, and coveralls to minimize the risk of direct contact with epoxy resin. These protective measures act as a barrier between your skin and the resin, reducing the chances of irritation or allergic reactions.

- Ensure proper ventilation: Adequate ventilation is essential, especially when spraying or sanding epoxy resin. This helps to minimize the inhalation of fumes and dust particles, protecting your respiratory system.

- Store components correctly: Store epoxy resin components in sealed containers in a dry place within the recommended temperature range of 65-90 degrees F. Improper sealing, exposure to direct sunlight, or storing near heat sources can lead to decreased shelf life and reduced performance.

- Consider suitable storage locations: Store epoxy resin in insulated garages, regulated indoor temperatures, or suitable locations away from direct sunlight and UV exposure. Additionally, personal experiences, such as using plastic bags to prevent hardening, can help prolong the shelf life and workability of epoxy resin.

Proper Storage Techniques for Epoxy Resin

Ensure the safe handling and longevity of epoxy resin by implementing proper storage techniques. Proper storage techniques are crucial to enhance the storage stability of two-component epoxy resin systems.

To begin with, it’s important to store epoxy resin in a cool, dry place, away from direct sunlight and extreme temperatures. Exposure to high temperatures may cause the resin to cure prematurely, rendering it unusable.

Additionally, it’s advisable to store epoxy resin in its original container, tightly sealed to prevent moisture absorption and evaporation. This helps maintain the resin’s chemical integrity and extends its shelf life.

Furthermore, it’s essential to keep the resin away from sources of ignition, as epoxy resin is flammable.

Ventilation Requirements for Epoxy Resin Handling

Properly ventilating the area is crucial for handling epoxy resin to ensure the safety of individuals and maintain the integrity of the material. When working with epoxy resin, consider the following ventilation requirements:

- Air Exchange: Adequate ventilation is necessary to remove fumes and prevent the buildup of potentially hazardous vapors. Ensure that the area has sufficient air exchange to maintain clean and fresh air. This can be achieved by using fans, opening windows, or utilizing an exhaust system.

- Enclosed Areas: When spraying epoxy resin as a coating or sanding in enclosed spaces, the risk of inhaling fumes increases. In such scenarios, it’s essential to have a well-ventilated space with proper airflow. Consider using additional ventilation equipment, such as industrial-grade fans or local exhaust systems, to effectively remove vapors.

- Respiratory Protection: While ventilation helps in reducing fumes, it’s also important to wear appropriate respiratory protection, such as masks, to minimize the risk of inhaling vapors. This is particularly crucial when working in poorly ventilated areas or during activities that generate a high concentration of fumes.

- Compliance with Guidelines: Follow the manufacturer’s guidelines for storing epoxy resin properly. Ensure that the components are stored in sealed containers in a dry place within the recommended temperature range of 65-90 degrees Fahrenheit. Avoid refrigeration and proximity to heat sources to prevent degradation.

Common Mistakes in Epoxy Resin Storage

Common mistakes in epoxy resin storage can compromise the integrity and performance of the material if not properly addressed. It is important to be aware of these mistakes and take proper precautions to ensure the longevity and effectiveness of your epoxy resin. Here are some common mistakes to avoid when storing epoxy resin:

| Mistake | Description |

|---|---|

| Not sealing the containers properly | Failing to seal the resin containers tightly can allow air to enter and degrade the resin over time. This can lead to a decrease in performance and quality. |

| Storing epoxy resin in direct sunlight | Exposure to sunlight can cause the resin to cure prematurely, resulting in reduced shelf life. It is best to store epoxy resin in a cool and dark area to maintain its effectiveness. |

| Failing to store at recommended temperature range | Epoxy resin should be stored within the recommended temperature range of 65 to 90 degrees Fahrenheit. Storing outside of this range can cause crystallization and impact the resin’s performance. |

| Storing near heat sources | Placing epoxy resin containers near heat sources can accelerate the degradation process and affect the quality of the resin. It is important to keep them away from heaters or other sources of heat. |

| Using improper containers | Using containers that are not specifically designed for epoxy resin storage can lead to contamination and moisture entry. This can compromise the viability of the resin and affect its performance. |

Tips for Cleaning Up Epoxy Resin Spills

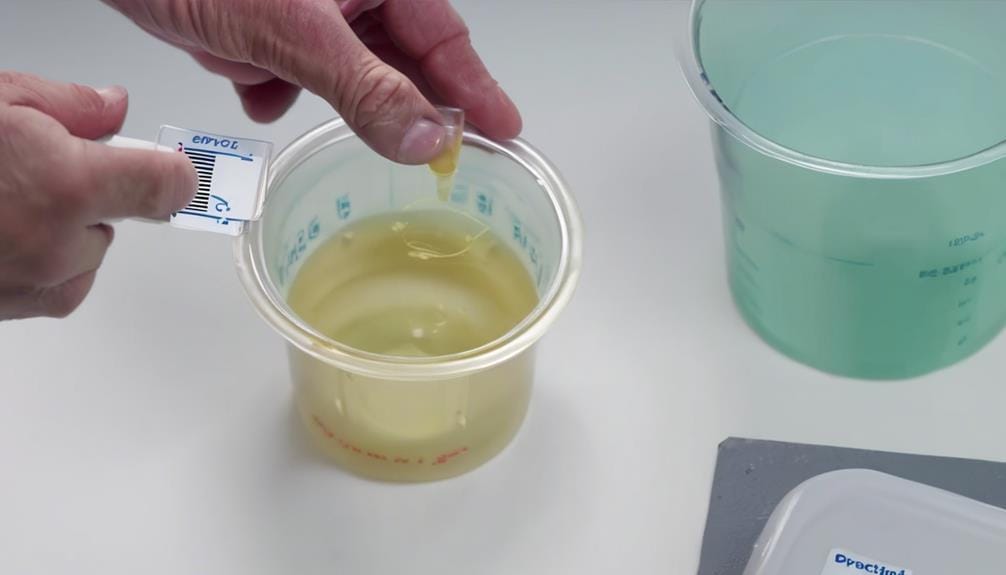

When it comes to handling epoxy resin spills, it’s crucial to follow proper cleaning procedures to ensure a safe and effective cleanup process. Here are some tips to help you clean up epoxy resin spills efficiently:

- Wear protective gear: Before you start cleaning up the spill, make sure to wear gloves and safety glasses to protect yourself from any potential hazards.

- Use suitable cleaning agents: To effectively clean up epoxy resin spills, use cleaning agents such as acetone or isopropyl alcohol. These solvents can help dissolve the resin and make it easier to remove.

- Act promptly: It’s important to clean up epoxy resin spills as soon as possible. If left unattended, the resin can harden and become more difficult to remove. Prompt action can prevent further complications.

- Proper disposal: When disposing of the cleaning materials used to clean up epoxy resin spills, make sure to follow proper disposal methods. Some resins may contain hazardous materials, so it’s important to dispose of them in accordance with local regulations.

Disposal Guidelines for Epoxy Resin

To ensure the safe and legal disposal of epoxy resin, it’s important to follow proper guidelines and regulations. Proper disposal methods for epoxy resin and its containers are necessary to protect both human health and the environment.

When handling epoxy resin, consider reusing any leftover material for future projects, if possible. This minimizes waste and reduces the need for disposal.

If disposal is necessary, it’s crucial to dispose of epoxy drums in a legal and safe manner. Cured epoxy, when mixed correctly, isn’t considered hazardous. However, empty containers should be cured before disposal. This can be done by allowing the epoxy to fully harden and cure, and then disposing of it according to local regulations.

It’s important to note that disposal methods may vary depending on your location. Therefore, it’s essential to check local regulations to ensure compliance with proper disposal guidelines for epoxy resin and its containers.

Frequently Asked Questions

How Should You Store Epoxy Resin?

To properly store epoxy resin, you should follow specific guidelines. Ensure proper storage temperature and ventilation, tightly seal containers to prevent air exposure, and use suitable containers. These steps will help maintain the resin’s viability and shelf life.

How Do You Handle Epoxy Resin Safely?

To handle epoxy resin safely, remember to take necessary precautions and wear proper safety equipment. Protect yourself with gear like safety glasses and gloves. Prioritize safety and follow guidelines for safe handling.

Can Epoxy Be Stored in Garage?

Yes, epoxy can be safely stored in a garage as long as the temperature requirements are met. Insulated garages with stable temperatures can provide suitable storage conditions for epoxy, ensuring its stability and usability.

Can You Store Epoxy Resin Outside?

You should not store epoxy resin outside as it can be negatively affected by environmental factors such as temperature fluctuations and exposure to sunlight. Proper indoor storage is essential to maintain its quality and performance.

Conclusion

In conclusion, proper storage and handling of epoxy resin are crucial for maintaining safety and cost efficiency.

By following manufacturer guidelines, using protective gear, and ensuring adequate ventilation and temperature control, the shelf life and performance of the resin can be extended.

Avoiding common mistakes such as improper sealing and exposure to sunlight is essential.

By implementing these measures, the risk of crystallization and contamination can be minimized, leading to improved resin performance and longevity.