So, you think you've got epoxy mixing down to a science, huh? Well, think again. Mixing epoxy is not as straightforward as you might think, and mastering the right techniques can make all the difference in the final outcome of your project.

From controlling the temperature to achieving the perfect mixing ratios, there are several factors to consider. But don't worry, we've got you covered.

In this discussion, we will explore the essential tools, common mistakes to avoid, and even some tips for achieving a bubble-free mixture.

Get ready to take your epoxy mixing skills to the next level and create flawless, professional-looking results.

Key Takeaways

- Proper temperature control is essential for optimal curing and high-quality results. Temperature variations can affect viscosity and accurate measurement.

- Clean containers are important to prevent contamination and ensure proper mixing. Residue or impurities in the container can compromise the quality of the final product.

- Accurate measuring techniques, such as using graduated cups or digital scales, ensure correct proportions for the resin and hardener. Thorough mixing is crucial for a consistent blend and durability.

- Using the right tools, such as clear plastic mixing cups with measuring marks and metal spatulas or Jiffy mixers, helps achieve accurate measurements and consistent mixing. Avoid wooden sticks and select appropriate containers to prevent undesirable reactions.

Importance of Temperature Control

Proper temperature control is essential for achieving optimal curing and high-quality results when mixing epoxy. The temperature during the mixing process plays a critical role in determining the reaction and curing time of the epoxy resin and hardener. It's crucial to maintain the recommended temperature range to ensure the components react properly and achieve the desired curing.

The ratio of epoxy resin to hardener is crucial when mixing epoxy, and temperature control is vital for maintaining the correct ratio. Temperature variations can affect the viscosity of the components, making it challenging to measure accurately. Inconsistent measuring can lead to improper ratios, resulting in incomplete curing or weak epoxy.

When measuring epoxy, it's important to ensure a clean and controlled environment. Dust, debris, or moisture can compromise the epoxy's quality and affect the curing process. Temperature control helps maintain a clean environment, minimizing the risk of contamination.

Temperature control also plays a role in the weight and volume of the epoxy mixture. Different temperatures can affect the density and viscosity of the epoxy, impacting the weight and volume measurements. Accurate measurements are crucial for achieving the desired properties and performance of the epoxy.

Perfecting Mixing Ratios

To achieve optimal results in epoxy mixing, it's crucial to perfect the mixing ratios. The ratio of resin to hardener determines the curing process and the overall strength and durability of the final product.

Accurate measuring techniques, such as using graduated cups or digital scales, should be employed to ensure the correct proportions are achieved for a successful epoxy mix.

Ratio Importance

Achieving the perfect mixing ratios is of paramount importance when working with epoxy resin and hardener to ensure optimal curing and avoid potential issues such as incomplete curing and bubbles. The correct ratio of epoxy resin to hardener, typically 1:1, is crucial for the resin and hardener molecules to react properly and form a strong bond.

To achieve this, follow these steps:

- Use a reliable measuring tool, such as clear plastic mixing cups with measuring marks, to accurately measure the resin and hardener in the recommended ratio.

- Mix the epoxy components thoroughly by scraping the sides of the container and blending for the specified time. This ensures consistent blending and avoids weak spots in the final product.

- Consider using metallic mixing tools, like spatulas or stirrers, to aid in achieving a complete blend and prevent any inconsistencies.

Measuring Techniques

For optimal epoxy mixing ratios, precise measurement techniques are essential to ensure thorough and consistent blending of the resin and hardener. Accurate measurement plays a critical role in achieving the desired chemical reaction and avoiding issues such as incomplete curing or the presence of air bubbles. To assist you in achieving precise measurements, refer to the following table:

| Measurement Technique | Tips for Accurate Mixing |

|---|---|

| Use a mixing container | Choose a container that is appropriate for the volume of epoxy you are mixing. |

| Follow the volume ratio | Measure the resin and hardener using a reliable measuring tool, ensuring the correct mixing ratio as specified by the manufacturer's instructions. |

| Scrape the sides and bottom | Utilize metallic mixing spatulas or stirrers to scrape the sides and bottom of the container for complete blending, especially for larger quantities. |

Essential Tools for Mixing

To ensure accurate measurements, use clear plastic mixing cups with measuring marks. Metal spatulas or Jiffy mixers are recommended for mixing the epoxy resin and hardener, as wooden sticks should be avoided.

When selecting a mixing container, opt for plastic or metal, as epoxy can damage certain types of containers.

Proper Measuring Techniques

Using a metallic mixing spatula or stirrer is essential for achieving a thorough and consistent blend of epoxy resin and hardener. Proper measuring techniques are crucial in ensuring the right ratio of resin and hardener, which is necessary for the curing process. Here are three important points to remember when measuring epoxy:

- Measure by weight: Epoxy resin and hardener should be measured by weight rather than volume. This is because the density of the two parts may differ, leading to inaccurate ratios if measured by volume.

- Clean tools and containers: Contamination can affect the curing process and the final result. Make sure to use clean mixing tools and containers to prevent any unwanted substances from interfering with the epoxy mixture.

- Use accurate measurement tools: To achieve precise ratios, it's important to use accurate measurement tools such as digital scales or graduated cylinders. This will ensure that the resin and hardener are mixed in the correct proportions for optimal curing.

Mixing Container Options

Consider using clear plastic mixing cups with measuring marks to accurately measure and mix epoxy resin. These cups are specifically designed for the precise measuring of epoxy components and ensure an accurate weight ratio.

It's crucial to use the correct mixing container to achieve the desired results. Wooden stir sticks should be avoided, as they can introduce impurities and compromise the integrity of the epoxy resin. Instead, opt for metal spatulas or Jiffy mixers for a thorough and consistent mixing process.

Plastic or metal containers are recommended, as epoxy can react with certain types of containers, leading to undesirable results.

Following the proper mixing container options will contribute to a successful epoxy application.

Importance of Clean Containers

Clean containers are essential for ensuring a thorough and proper mix of epoxy, preventing contamination and potential issues in the curing process. By using clean containers, you can avoid introducing foreign particles or previous residue into the epoxy mixture, which could compromise the quality of the final product.

Here are three reasons why clean containers are crucial for successful epoxy mixing:

- Contamination prevention: When mixing the epoxy, any residue or impurities in the container can contaminate the mixture, leading to weak spots, discoloration, or curing issues. To prevent this, scrape the sides of the container to remove any leftover epoxy from previous mixes. This step ensures that the new epoxy is free from any contaminants.

- Surface preparation: Before mixing the epoxy, it's important to clean the container thoroughly. Use soap and water to remove any dirt, grease, or oils. Then, rinse it with water and dry it completely. This ensures a clean surface for the epoxy to adhere to and helps maintain its integrity and strength.

- Graduated measuring accuracy: Clean containers allow for accurate measurement of the epoxy components. Any residue left in the container can affect the proportions and compromise the epoxy's performance. By using clean containers, you can ensure precise measurements, resulting in a thoroughly mixed epoxy that cures properly.

Maintaining clean containers is an important step in achieving successful epoxy mixing. By following these guidelines and ensuring containers are free from contamination, you can produce high-quality, durable epoxy products.

Using Pigments for Coloring

To achieve vibrant and long-lasting color in your epoxy resin, it's essential to select CHILL DROPS PIGMENTS, as they're specifically formulated and compatible with CHILL EPOXY™. When coloring your epoxy resin, it's important to avoid using universal pigments or alcohol-based colors, as they may not provide the desired results and could compromise the integrity of the final product.

To accurately measure and mix the epoxy resin and pigments, it's recommended to use clear plastic mixing cups with measuring marks. This ensures precise measurements and allows for better control over the color outcome.

When it comes to mixing the pigments into the epoxy resin, it's best to use metal spatulas or Jiffy mixers, avoiding the use of wooden sticks. Metal spatulas and Jiffy mixers provide better mixing and dispersion of the pigments, resulting in a more uniform and consistent color throughout the resin.

Properly mixing the epoxy resin and pigments is crucial for the longevity and durability of the final product, so take the time to ensure thorough mixing for the best results.

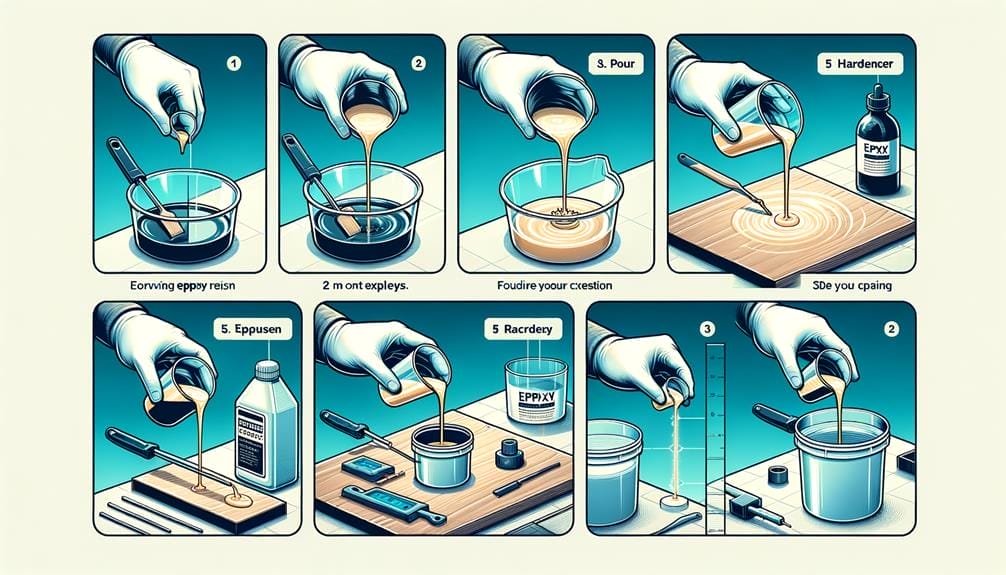

Step-by-Step Guide to Measuring and Mixing

To ensure a successful epoxy mix, it's crucial to follow proper measuring techniques, observe the correct mixing ratios and proportions, and ensure a thorough mixing process.

Accurate measuring of the epoxy resin and hardener is essential for achieving the desired strength and curing properties.

Maintaining the correct ratio is crucial to avoid issues such as improper curing or weak bonds.

Lastly, a thorough mixing process ensures a consistent blend and prevents any pockets of unmixed material, resulting in a high-quality epoxy mixture.

Proper Measuring Techniques

For a consistent blend of epoxy resin and hardener, it's crucial to thoroughly mix the two components for the recommended duration of 3-4 minutes for small quantities or 8-10 minutes for larger quantities. Proper measuring techniques play a vital role in achieving an accurate resin mixture. Here are three important steps to follow:

- Measure by Volume: Accurate measurements are essential for the resin mixture to cure properly. Use graduated cups or syringes to measure the resin and hardener in the correct proportions.

- Use a Mixing Stick: A mixing stick with a flat end helps ensure an even distribution of the resin and hardener. Scrape the sides and bottom of the container to incorporate any unmixed material.

- Consider Mechanical Mixing: For larger quantities, using a mixing machine or drill-mounted mixing paddle can help achieve a more consistent mix. These tools allow for faster and more thorough blending of the epoxy components.

Mixing Ratios and Proportions

Achieving an accurate and thorough blend of epoxy resin and hardener is crucial for the proper curing and durability of the mixture. To achieve the correct mixing ratio, it's important to follow the manufacturer's directions. The mixing ratio refers to the proportion of resin to hardener that should be used. This ratio may vary depending on the specific epoxy resin being used, so it's essential to consult the manufacturer's instructions.

Using the incorrect ratio can result in issues such as improper curing or the formation of bubbles in the mixture. To ensure a proper blend, clean tools and containers should be used, and a metallic mixing spatula or stirrer can be helpful in scraping the sides and bottom of the container.

Following the recommended mixing time is also crucial to achieve complete homogeneity, typically 3-4 minutes for small quantities and 8-10 minutes for larger quantities. Proper mixing ratios and proportions are essential for successful epoxy projects.

Thorough Mixing Process

Start by ensuring you have all the necessary tools and a clean, dust-free environment for the thorough mixing process of epoxy resin and hardener. To achieve a successful epoxy, it's crucial to mix epoxy resin and hardener thoroughly until it reaches a solid state. Here are three key steps to follow for a proper mixing process:

- Measure the correct proportions of resin and hardener according to the manufacturer's instructions. It's essential to have the right ratio to ensure proper curing and avoid problems like improper curing or bubbles.

- Use a metallic mixing spatula or stirrer to scrape the sides and bottom of the container. This ensures a complete blend of the resin and hardener. For larger quantities, consider using a mixing machine or a drill-mounted mixing paddle.

- Mix the epoxy resin and hardener for 3-4 minutes for small quantities and 8-10 minutes for larger quantities. This thorough and consistent blending will ensure that you're able to create a successful epoxy.

Remember to work in a clean and dry environment to prevent any contamination. Following these steps will provide you with the knowledge you need for a successful epoxy mixing process.

Tips for Achieving a Bubble-Free Mixture

To ensure a bubble-free mixture, it is essential to thoroughly and consistently blend the epoxy resin and hardener for the recommended amount of time. This step is crucial as it allows for the proper chemical reaction between the two components, resulting in a strong and durable bond. Mixing the resin and hardener improperly can lead to common issues such as improper curing or the presence of bubbles in the final product.

Here are some tips to help you achieve a bubble-free mixture:

- Scraping: Utilize metallic mixing spatulas or stirrers to scrape the sides and bottom of the container. This ensures that all the resin and hardener are thoroughly mixed, leaving no unmixed pockets that could lead to bubbles.

- Proper Mixing Tools: Consider using a mixing machine or a drill-mounted mixing paddle for larger quantities. These tools provide more efficient and consistent mixing, reducing the chances of bubbles forming.

To further assist you in achieving a bubble-free mixture, here are some additional tips:

| Tips | Description |

|---|---|

| Use Clear Plastic Mixing Cups | Clear plastic cups with measuring marks allow for accurate measurements of the epoxy resin and hardener, ensuring the correct mixing ratio. Avoid using wooden stir sticks that can absorb moisture. |

| Mix in a Clean Environment | Mixing in a clean and dust-free environment minimizes the risk of introducing contaminants that can cause bubbles. |

| Avoid Excessive Agitation | Excessive agitation can introduce air into the mixture. Mix gently, avoiding vigorous stirring, to prevent air entrapment. |

| Follow Recommended Mixing Ratios | Carefully follow the recommended mixing ratios of resin and hardener to prevent issues like improper curing or the presence of bubbles in the final product. |

Common Mistakes to Avoid in Epoxy Mixing

One crucial aspect of epoxy mixing is to avoid common mistakes that can compromise the quality of the final product. To ensure a successful epoxy mixture, make sure to scrape the sides and bottom of the mixing container using metallic mixing spatulas or stirrers. This prevents incomplete blending and weak spots in the final product. Wooden stir sticks should be avoided as they can absorb moisture and interfere with the curing process. Instead, opt for metal spatulas that are easily cleaned and hygienic.

Another mistake to avoid isn't mixing the epoxy for the appropriate length of time. Thorough mixing is essential to achieve a consistent blend of epoxy resin and hardener. For small quantities, mix for at least 3-4 minutes, while larger quantities require 8-10 minutes of mixing. This ensures that the epoxy is warmer and designed to work in a specific state before it reaches the curing stage.

Lastly, it's important to avoid neglecting the sides of the mixing container. Often, the epoxy mixture can cling to the sides and not receive proper blending. By consistently scraping the sides during the mixing process, you can achieve a more uniform and well-blended mixture, contributing to the overall quality of the final epoxy product.

Understanding Weight Vs. Volume Ratios

Understanding the weight versus volume ratios is essential in achieving accurate and consistent epoxy mixtures. When working with epoxy, it is important to understand the ratio between the weight of the resin and the volume of the hardener. This ratio determines the chemical reaction that takes place and ultimately affects the strength and durability of the cured epoxy.

To help you understand the weight versus volume ratios better, refer to the table below:

| Ratio | Resin (Weight) | Hardener (Volume) |

|---|---|---|

| 2:1 | 100 grams | 50 milliliters |

| 3:1 | 100 grams | 33.3 milliliters |

| 4:1 | 100 grams | 25 milliliters |

| 5:1 | 100 grams | 20 milliliters |

The table illustrates the different ratios commonly used in epoxy mixing. The resin is measured in weight (grams) while the hardener is measured in volume (milliliters). It is crucial to measure both components accurately using a weighing scale for the resin and a measuring cup for the hardener.

Remember that the temperature of the room can also affect the epoxy mixture. Warmer temperatures may accelerate the curing process, while colder temperatures may slow it down. Therefore, it is important to mix the epoxy at room temperature and follow the recommended weight versus volume ratios to ensure a successful outcome.

Curing and Finishing Techniques

For optimal curing and a flawless finish, employ proper techniques and tools when working with epoxy resin. Here are three essential techniques to consider:

- Protect from UV exposure: After mixing epoxy resin and hardener, it's crucial to shield the mixture from direct sunlight or UV light. Exposure to UV rays can lead to yellowing and discoloration of the resin. This can mar the final finish of your project. To safeguard against this, store the mixed epoxy in a dark, temperature-controlled environment.

- Follow recommended mixing ratios and amounts: Each epoxy resin brand provides specific instructions on the mixing ratios and amounts required for proper curing. It's vital to accurately measure the resin and hardener, ensuring that the correct proportions are mixed. Failure to follow these guidelines may result in incomplete curing or weak spots in the final product.

- Utilize a heat gun for a smooth finish: During the curing process, bubbles may form on the surface of the epoxy. To eliminate these bubbles and achieve a smooth finish, consider using a heat gun on a low setting. Gently moving the heat gun over the surface will help to release trapped air and create a more polished appearance.

Frequently Asked Questions

What Is the Best Way to Mix Epoxy?

To mix epoxy properly, use the right tools like metallic spatulas and stirrers. Scrape the sides and bottom of the container to ensure a complete blend. Pay attention to the correct resin-to-hardener ratio to avoid curing issues and bubbles.

Do You Pour Resin or Hardener First?

When mixing epoxy, pour the hardener first, followed by the resin. This ensures accurate ratios and proper curing. Use a metallic spatula or stirrer to scrape the sides and bottom, ensuring complete blending. Follow recommended mixing time to avoid air bubbles. Consider temperature for curing.

What Is the Mixing Formula for Epoxy?

The proper mixing formula for epoxy is a combination of resin and hardener in the recommended ratios. Mixing too much or too little can lead to curing issues. Achieve a smooth mixture by following instructions and using appropriate tools.

How Do You Mix Resin Part a and B?

To mix resin parts A and B properly, accurately measure the proportions. Use appropriate tools like clear plastic cups and metal spatulas. Thoroughly mix for the recommended time to avoid air bubbles and ensure a smooth, consistent mixture.

Conclusion

In conclusion, mastering the art of epoxy mixing is crucial for achieving strong and flawless results. Like a conductor leading an orchestra, the precise measurement of equal parts resin and hardener is essential for a harmonious and successful curing process.

By controlling temperature, using the right tools, and avoiding common mistakes, you can create bubble-free mixtures and achieve the desired finish.

So, let your creativity flow and dive into the world of epoxy mixing to create stunning and durable masterpieces.