Did you know that the curing time for epoxy resin can vary depending on various factors?

For example, you might be able to walk on the surface after 24 hours, but full curing can take up to a week.

It’s fascinating to discover how temperature, humidity, and the thickness of the epoxy layer can all play a role in determining how long it takes for the resin to dry.

But what is the ideal temperature for epoxy resin curing? And are there any safe methods to reduce the curing time?

In this discussion, we will explore these questions and more, unraveling the mysteries behind the drying process of epoxy resin.

So, let’s dive in and discover the secrets of epoxy resin curing time.

Key Takeaways

- Temperature is a critical factor that affects epoxy resin curing time.

- The ideal temperature range for epoxy resin curing is 75-85ºF (24-30ºC).

- Warmer temperatures accelerate the curing process, while colder temperatures slow it down.

- Proper ratios and mixing techniques are essential for achieving a consistent and thorough cure.

Factors Affecting Epoxy Resin Curing Time

The curing time of epoxy resin is influenced by various factors, which can significantly impact the final results of your project. Understanding these factors is crucial for achieving the desired outcome.

One of the primary factors affecting epoxy resin curing time is temperature. Higher temperatures accelerate the curing process, while lower temperatures slow it down. It’s important to note that extreme temperatures can also negatively affect the final quality of the cured resin.

Another factor to consider is the thickness of the epoxy resin. Thicker layers take longer to cure compared to thinner ones. This is because the heat generated during curing is trapped within the resin, increasing the curing time.

Additionally, the type of epoxy resin used can affect the curing time. Different formulations have different curing properties, and it’s essential to choose the right resin for your specific project requirements.

Finally, the presence of additives or fillers in the epoxy resin can also impact the curing time. Certain additives may speed up or slow down the curing process, depending on their chemical composition and interactions with the resin.

Ideal Temperature for Epoxy Resin Curing

To ensure optimal curing of epoxy resin, it’s crucial to maintain a temperature range of 75-85ºF (24-30ºC). Higher temperatures expedite the curing process, while cooler temperatures significantly slow it down.

Temperature control methods, such as using a temperature-controlled room or heating blankets, can help maintain the ideal curing temperature and ensure consistent results.

Optimal Curing Temperature

Maintaining a consistent temperature within the optimal range of 75-85°F (24-30°C) is crucial for achieving the desired curing time for epoxy resin.

Here are some important points to consider regarding the optimal curing temperature:

- Warmer temperatures can significantly accelerate the curing process, reducing the overall cure time and allowing the epoxy resin to dry more quickly.

- On the other hand, colder temperatures can slow down the curing process, extending the cure time and delaying the drying of the epoxy resin.

- Variations in temperature can have a direct impact on the quality and final curing results, so it’s essential to maintain a consistent temperature throughout the curing process.

- By controlling the temperature within the recommended range, you can optimize the cure time for epoxy resin and ensure a successful and efficient curing process.

Effects of Temperature

When aiming to achieve the desired curing time for epoxy resin, it’s crucial to consider the effects of temperature, specifically the ideal temperature range of 75-85°F (24-30°C). Warmer temperatures facilitate the curing process, resulting in faster epoxy curing time.

On the other hand, colder temperatures slow down the curing process, prolonging the time it takes for the epoxy resin to cure fully. It’s important to note that adding more hardener to the mixture doesn’t increase the cure time for epoxy resin. In fact, it disrupts the delicate 1:1 mixing ratio and prevents proper curing.

To ensure faster epoxy curing time, it’s recommended to increase the temperature to the ideal range and maintain a constant temperature for the first 24 hours. By following these guidelines, you can achieve the desired cure time for your epoxy resin.

Temperature Control Methods

For optimal curing of epoxy resin, achieving the ideal temperature range of 75-85°F (24-30°C) is crucial. Proper temperature control methods can significantly impact the curing process and ensure the desired results. Consider the following methods to maintain the ideal temperature for epoxy resin curing:

- Ambient temperature: Ensure that the room temperature falls within the recommended range. This provides a stable environment for the resin to cure properly.

- Heat gun: If the ambient temperature is lower than the ideal range, using a heat gun can help warm up the resin and accelerate the curing process.

- Faster curing resin: Choosing a resin with a faster curing time can be beneficial, especially when working in cooler temperatures.

- Consistent temperature: It’s essential to maintain a consistent temperature throughout the curing process. Fluctuations can hinder the resin’s ability to cure evenly.

How Long Does Epoxy Resin Take to Dry?

The drying time of epoxy resin can vary depending on the curing method, environmental factors, and the specific type of resin used. Factors such as temperature, humidity, and exposure to sunlight or UV rays can affect the dry time of epoxy resin. Additionally, the type of resin and curing method chosen will also impact the curing time.

To give you an idea of the range of drying times, here is a table showcasing the typical curing times for different epoxy resin curing methods:

| Curing Method | Curing Time |

|---|---|

| UV Light | 30 seconds |

| Hot Curing | Few hours |

| Natural Drying | At least two weeks |

As you can see, the curing time can vary significantly depending on the method chosen. UV light curing is the fastest method, taking only 30 seconds. Hot curing can take a few hours, while natural drying requires a minimum of two weeks for full hardening.

To accelerate the curing process, you can increase the ambient temperature, opt for a faster-curing resin, or add a curing agent. However, it is important to handle, store, and prepare epoxy resin properly to achieve the desired drying time.

Determining When Epoxy Resin Is Fully Cured

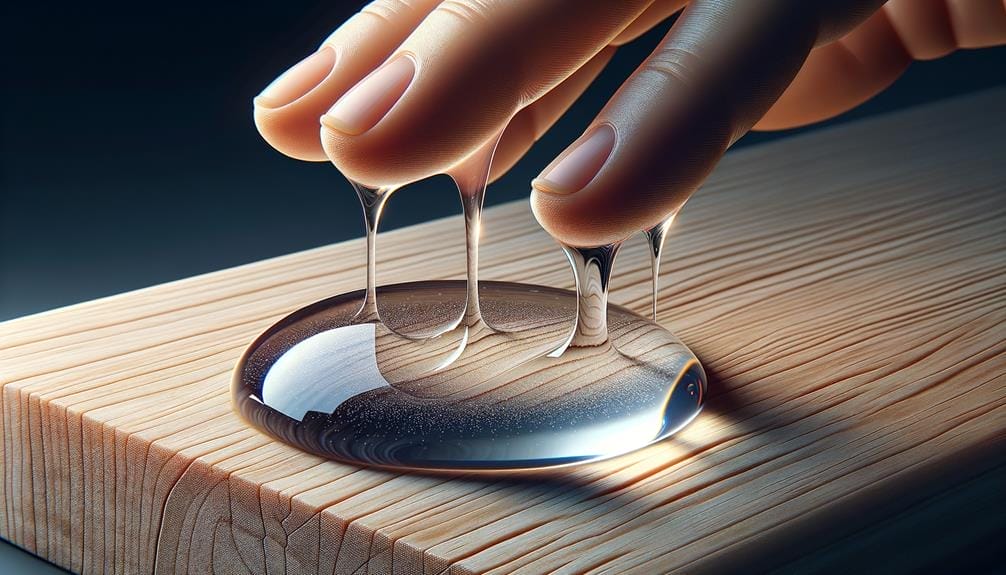

To determine the full curing of epoxy resin, check for dryness and lack of tackiness in the resin. This will indicate that the resin has completed the curing process and is ready for use.

Additionally, there are a few other methods to determine the complete curing of epoxy resin:

- Use a commercial durometer to measure the hardness. Aim for at least a 60 reading on the Shore D scale for complete curing. This test will provide a quantitative measurement of the resin’s hardness, ensuring it has reached the desired level of hardness for optimal performance.

- Consider using leftover resin in a cup to test hardness before touching or unmolding the finished project. This allows you to assess the curing progress without risking damage to the final product.

- Ensure that the cured resin has a dry touch. Avoid any tackiness, as this can indicate incomplete curing. A dry touch is a reliable indicator that the epoxy resin has fully cured.

- Always follow the manufacturer’s instructions and recommended curing times. Each epoxy resin product may have different curing requirements, so it’s essential to adhere to the specific guidelines provided to ensure proper hardening.

Epoxy Resin Drying Time for 2-Part Epoxy

Epoxy resin drying time for 2-part epoxy can vary depending on several factors, such as resin type, ambient temperature, humidity levels, and UV exposure. The curing process of epoxy resin involves a chemical reaction between the resin and the hardener. This reaction leads to the formation of a solid, durable material. The cure time for epoxy resin typically ranges from a few hours to two weeks.

The ambient temperature plays a significant role in determining the drying time of epoxy resin. Higher temperatures accelerate the curing process, while lower temperatures slow it down. It’s essential to follow the manufacturer’s instructions regarding the recommended temperature range for curing the specific epoxy resin.

Humidity levels can also affect the drying time of epoxy resin. High humidity can extend the cure time as it slows down the evaporation of moisture from the resin. Conversely, low humidity can speed up the drying process.

UV exposure can also influence the curing time of epoxy resin. Some epoxy resins cure through a process called UV curing, which involves exposure to ultraviolet light. UV exposure helps to initiate and accelerate the curing process, reducing the overall drying time.

Understanding Why Epoxy Resin Takes Time to Cure

Understanding the curing time of epoxy resin requires an examination of various factors that influence the process. Epoxy resin is a versatile material that’s used in a wide range of applications, from construction to arts and crafts. However, one common characteristic of epoxy resin is that it takes time to cure.

Here are some reasons why epoxy resin takes time to cure:

- Temperature: The temperature at which epoxy resin is cured can greatly affect the curing time. Higher temperatures generally result in faster curing, while lower temperatures can slow down the process. It’s important to follow the manufacturer’s instructions regarding the recommended temperature range for curing epoxy resin.

- Humidity: The level of humidity in the environment can also impact the curing time of epoxy resin. Higher humidity levels can slow down the curing process, while lower humidity levels can speed it up. It’s important to ensure that the curing environment has the appropriate humidity level for optimal curing.

- Resin-Hardener Ratio: The correct ratio of resin to hardener is crucial for proper curing. An inaccurate ratio can lead to incomplete curing or extended curing time. It’s important to measure the resin and hardener accurately and mix them thoroughly.

- Mixing Techniques: Proper mixing techniques are essential for achieving a consistent and thorough cure. Inadequate mixing can result in uneven curing or incomplete curing. It’s important to follow the manufacturer’s instructions regarding the recommended mixing techniques for epoxy resin.

Tips for Accelerating Epoxy Resin Curing

To accelerate the curing of epoxy resin, there are several tips you can follow.

First, consider using heat sources such as heat guns or heating pads to increase the ambient temperature and speed up the curing process.

Additionally, adjusting the mixing ratios and temperatures can also help accelerate the curing time.

Lastly, utilizing UV light can be an effective method, as it can cure epoxy resin in as little as 30 seconds.

Heat Sources for Curing

Using a heat gun or blow dryer can significantly speed up the curing process of epoxy resin. By applying heat, you can reduce the cure time and achieve faster results. Here are some heat sources that you can use to accelerate the curing of epoxy resin:

- Increase the ambient temperature: By raising the temperature of the surrounding environment, you can promote faster resin curing.

- Use a resin with a faster curing time or a higher ratio of hardener to resin: Choosing a resin with a shorter curing time or increasing the amount of hardener can expedite the curing process.

- Add curing agent or accelerator: Introducing an extra curing agent or accelerator can help speed up the reaction and enhance the curing of epoxy resin.

- Place a space heater or heat lamp near the artwork: Positioning a heat source, such as a space heater or heat lamp, in close proximity to the resin can encourage faster curing.

Mixing Ratios and Temperatures

To expedite the curing process of epoxy resin, it’s crucial to consider the mixing ratios and temperatures for achieving optimal results.

The cure time for epoxy resin can be significantly affected by the ratio at which the resin and hardener are mixed. It’s recommended to strictly follow the manufacturer’s instructions regarding the correct mixing ratio to ensure proper curing. Deviating from the specified ratio can result in incomplete curing or a weakened final product.

Additionally, temperature plays a vital role in epoxy resin curing. Higher temperatures can accelerate the curing process, while lower temperatures can slow it down. It’s important to note that extreme temperatures can negatively impact the curing process and the final strength of the epoxy resin.

Therefore, maintaining the recommended temperature range during curing is essential for achieving the desired results.

UV Light and Curing

UV light can be utilized to accelerate the curing process of epoxy resin, reducing the curing time to as little as 30 seconds. This method is known as UV light curing and is commonly used in industries that require fast and efficient curing of epoxy resin.

Here are four ways in which UV light can accelerate the curing of epoxy resin:

- UV lamps: These specialized lamps emit high-intensity UV light, which triggers a chemical reaction in the resin, causing it to cure rapidly.

- UV curing chambers: These chambers provide a controlled environment where epoxy resin can be exposed to UV light from all angles, ensuring uniform and thorough curing.

- UV curing ovens: Similar to UV curing chambers, these ovens use UV light to cure epoxy resin, but they also provide the added benefit of temperature control, allowing for more precise curing conditions.

- UV curing adhesives: These adhesives contain special additives that react to UV light, allowing for quick and efficient bonding of materials.

Safe Methods to Reduce Epoxy Resin Curing Time

For a safe and efficient reduction in epoxy resin curing time, consider utilizing alternative methods such as increasing the ambient temperature or selecting a faster-curing resin.

By increasing the temperature of the environment, you can accelerate the curing process. This can be achieved by using a heat gun or blow dryer to apply heat to the resin. It’s important to note that excessive heat can cause the resin to cure too quickly, leading to potential issues such as cracking or incomplete curing. Therefore, it’s crucial to monitor the temperature closely and avoid overheating.

Another option to consider is selecting a resin with a faster curing time. Different epoxy resins have varying cure times, so choosing a resin with a quicker cure time can significantly reduce the overall curing time. Additionally, adjusting the ratio of hardener to resin can also expedite the curing process. However, it’s important to follow the manufacturer’s guidelines and not exceed the recommended ratio, as this can negatively impact the final result.

Furthermore, storing epoxy resin in a cool, dry place can help maintain its optimal curing properties. Exposure to high humidity or moisture can hinder the curing process and result in a longer cure time. Additionally, it’s essential to avoid using excessive color additives or incorrect measurements, as they can also interfere with the proper curing of epoxy resin.

Exploring Epoxy Curing Blankets

Now, let’s explore the use of epoxy-curing blankets for temperature control during the curing process.

These blankets provide a controlled environment that ensures optimal curing conditions, allowing for consistent and efficient results.

Temperature Control for Curing

To facilitate faster curing of epoxy resin, it’s recommended to explore the use of epoxy curing blankets, which help control the temperature during the curing process. Epoxy-curing blankets are designed to provide uniform and consistent heat distribution, ensuring an optimal environment for the epoxy to cure.

Here are four key benefits of using epoxy-curing blankets for temperature control during the curing process:

- Precise Temperature Control: Epoxy curing blankets allow you to set and maintain the desired temperature, ensuring that the epoxy resin cures at the optimal temperature range for efficient and effective curing.

- Faster Curing Time: By maintaining a consistent temperature, epoxy curing blankets help speed up the curing time of epoxy resin. This reduces the waiting time and allows you to complete your project more quickly.

- Uniform Heat Distribution: Epoxy curing blankets evenly distribute heat across the surface, preventing hot spots and ensuring that the epoxy resin cures uniformly. This helps to avoid uneven curing and potential quality issues.

- Easy to Use and Install: Epoxy curing blankets are designed for ease of use and installation. They can be wrapped around the epoxy resin project, providing a controlled environment for the curing process without the need for complex setups or equipment.

Time Required for Curing

When considering the time required for curing epoxy resin, exploring the use of epoxy curing blankets becomes crucial in maintaining optimal temperature control throughout the curing process. The curing time for epoxy resin can vary depending on various factors such as resin type, temperature, humidity, and exposure to sunlight or UV rays. UV light curing can take as little as 30 seconds, while hot curing involves applying heat to speed up the process. Higher temperatures generally reduce curing times. Epoxy undergoes three stages during the curing process: liquid, gel, and solid. It is important to ensure that the cured resin feels dry to the touch and is not tacky. A reading of at least 60 or higher on the Shore D scale indicates a fully cured epoxy. To accelerate curing, you can increase the ambient temperature, use a heat gun, use a resin with a faster curing time, increase the ratio of hardener to resin, or add a curing agent or accelerator.

| Factors Affecting Cure Time | Tips for Accelerating Cure Time |

|---|---|

| Resin type | Increase ambient temperature |

| Temperature | Use a heat gun |

| Humidity | Use a resin with a faster curing time |

| Exposure to sunlight/UV rays | Increase the ratio of hardener to resin |

| Add curing agent or accelerator | |

How to Make Epoxy Resin Dry Faster

You can expedite the drying process of epoxy resin by utilizing UV light, hot curing methods, or heat guns, with UV light curing taking as little as 30 seconds.

To make epoxy resin dry faster, consider the following methods:

- UV Light: Expose the resin to UV light, which triggers the curing process and can significantly reduce the cure time. UV light sources like UV lamps or sunlight can be used for this purpose.

- Hot Curing Methods: Increase the ambient temperature to accelerate the resin’s curing process. This can be achieved by placing the resin in a warm environment or using specialized equipment like heat blankets or ovens.

- Heat Guns: Directing a heat gun toward the resin can help speed up the curing time. Ensure that the heat gun is used at a safe distance and temperature to prevent any damage to the resin or surrounding objects.

- Adjusting the Curing Agents: Choosing a resin with a faster curing time or adjusting the hardener-to-resin ratio can affect the drying speed. Adding a curing agent can also expedite the curing process.

Remember to consider the resin type, temperature, humidity, and exposure to sunlight or UV rays, as these factors can influence the cure time. Proper handling and storage of the resin, such as keeping it in a cool and dry place away from direct sunlight or extreme temperatures, can also aid in faster curing.

Challenges and Factors Affecting Epoxy Resin Drying Time

Expedited drying of epoxy resin can be influenced by various challenges and factors that impact the resin’s curing time.

The cure time or drying time of epoxy resin is affected by several key factors.

First, the type of resin used plays a significant role. Different epoxy resins have varying curing times, with some taking longer than others.

Secondly, temperature is a crucial factor affecting drying time. Higher temperatures generally result in faster curing, while lower temperatures significantly slow down the process.

Thirdly, humidity levels can also impact epoxy resin drying time. High humidity can prolong the curing process, while low humidity can expedite it.

Additionally, exposure to sunlight or UV rays can affect drying time. The presence of these factors can either hasten or delay the curing process.

Lastly, accurate measurement and thorough mixing of epoxy resin and hardener are essential. Inaccurate ratios and incomplete mixing can lead to longer curing times.

It’s also important to store, handle, and prepare the epoxy resin properly, avoiding obstructions like excessive color additives and high humidity.

Frequently Asked Questions

How Do You Know When Epoxy Resin Is Fully Cured?

When the epoxy resin is fully cured, you can visually check for a dry and smooth surface, perform tactile testing to ensure it’s not tacky, and use chemical testing with a Shore D scale reading of at least 60.

How Long Should You Let Epoxy Resin Dry?

To achieve optimal drying conditions for epoxy resin, you should let it dry for the recommended curing time. Factors like temperature, humidity, and thickness of the resin can affect the drying time.

How Do You Slow Epoxy Curing Time?

To slow epoxy curing time, control the temperature by working in a cooler environment. Avoid using additives for cure time and choose a resin with a longer curing time or a lower hardener-to-resin ratio.

Can You Dry Epoxy With a Hair Dryer?

Yes, you can use a hair dryer to dry epoxy resin. Applying heat speeds up the curing process, but be careful to use low heat and keep the hair dryer at a safe distance to avoid damaging the resin.

Conclusion

In conclusion, it’s crucial to consider various factors such as temperature, humidity, and epoxy layer thickness when determining the curing time for epoxy resin. Following the manufacturer’s instructions and allowing sufficient time for full curing will ensure a strong and durable finish.

Additionally, exploring methods like epoxy-curing blankets and implementing safe techniques can help reduce the curing time. Remember, patience is key to achieving optimal results when working with epoxy resin.